Overview of Carbon Steel Hexagonal Nut Fasteners

Carbon steel hexagonal nut fasteners are essential mechanical components widely used across global industries. Their six sided structure provides excellent wrenching accessibility, strong torque resistance, and universal compatibility with standard bolts. Because of their stable performance and cost efficiency, carbon steel hexagonal nuts are among the most commonly used fastening elements in machinery, construction, automotive manufacturing, and industrial equipment.

Compared with other materials, carbon steel offers high strength, machinability, and wide adaptability, making it the preferred choice for general purpose fastening systems.

Advantages of Using Carbon Steel 4.8 Grade Hexagonal Nuts

Grade 4.8 hexagonal nuts are ideal for light to medium load applications. They are chosen for:

- A reliable tensile strength of around 400 MPa

- Good plasticity and resistance to cracking

- Lower material and processing cost

- Wide compatibility with standard bolts and threaded components

- Stable performance in indoor and controlled environments

The stability and affordability of grade 4.8 carbon steel nuts make them a popular choice for large scale production and assembly lines.

Mechanical Performance Comparison

| Material |

Grade |

Tensile Strength MPa |

Corrosion Resistance |

Cost |

Application |

| Carbon Steel |

4.8 |

400 |

Medium |

Low |

Machinery, furniture, metal structures |

| Carbon Steel |

8.8 |

800 |

Medium |

Medium |

Automotive, heavy equipment |

| Stainless Steel 304 |

A2 70 |

700 |

High |

Higher |

Outdoor equipment |

| Stainless Steel 316 |

A4 80 |

800 |

Very High |

High |

Marine environments |

Key Functional Features

- Precision machined threads ensure smooth tightening and removal

- High structural integrity suitable for vibration resistant assemblies

- Available in multiple standards such as DIN, ISO, GB, and ASTM

- Optional surface coatings for corrosion protection

- Compatible with both manual and automated tightening systems

Surface Treatment Options

To improve corrosion resistance and durability, carbon steel hexagonal nuts can be treated with:

- Zinc plating

- Hot dip galvanizing

- Dacromet coating

- Black oxide

- Phosphate coating

Choosing the right coating ensures better long term performance, especially in humid or corrosive environments.

Industrial Application Fields

Carbon steel hexagonal nuts are used in a wide variety of sectors, including:

- Machinery manufacturing

- Metal and steel structure assembly

- Automotive parts and chassis

- Appliance manufacturing

- Furniture and hardware

- Construction and civil engineering

- Pipeline supports and industrial frames

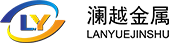

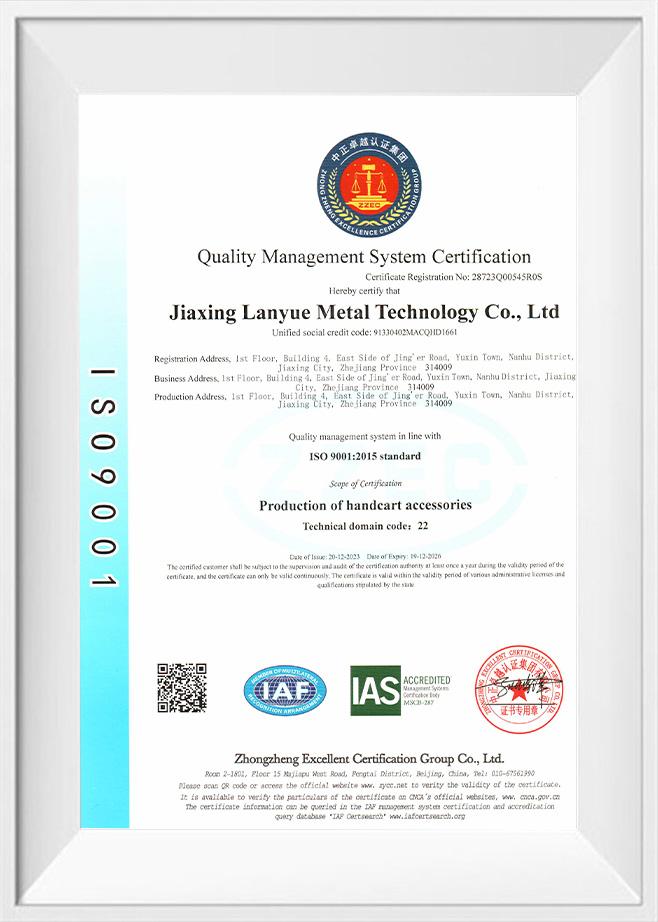

Why Choose Lanyue Metal Technology

Jiaxing Lanyue Metal Technology Co. Ltd. is located in Jiaxing, Zhejiang, one of the most advanced fastener manufacturing clusters in China. Our company focuses on the production, development, and engineering of precision metal and engineering plastic components.

- Complete ISO 9001 quality management system

- Advanced forming, threading, and testing equipment

- Strong supply capacity for global industrial clients

- Professional engineering team for custom solutions

- Stable quality and reliable delivery schedules

- Long term partnerships with international manufacturers

How to Select the Right Hexagonal Nut

| Factor |

Recommendation |

| Load Requirement |

Use grade 4.8 for general loads and higher grades for structural loads |

| Corrosion Environment |

Select proper coating such as zinc, galvanizing, or stainless steel options |

| Thread Standard |

Match ISO, DIN, GB, or ASTM with your bolts |

| Application Precision |

Choose precision threads for high accuracy assemblies |

| Budget |

Carbon steel 4.8 offers the best balance of cost and performance |

Additional Technical Notes

- Hexagonal nuts allow for tightening from multiple angles, making assembly easier in tight spaces

- Carbon steel allows high repeatability during mass production

- Thread accuracy directly affects the stability of the entire fastening system

- Correct nut and bolt pairing ensures maximum load efficiency

Frequently Asked Questions

Q1 Are carbon steel 4.8 nuts suitable for dynamic loads

They are suitable for moderate dynamic loads. For heavy vibration or impact loads, higher grades such as 8.8 are recommended.

Q2 What coating is best for outdoor conditions

Hot dip galvanizing provides excellent outdoor corrosion resistance, especially for construction or exposed metal structures.

Q3 Can Lanyue Metal offer OEM and custom production

Yes. We offer custom specifications, thread types, surface treatments, materials, and packaging based on your project requirements.

Q4 What industries commonly use grade 4.8 nuts

General machinery, furniture, indoor installations, automotive components, and equipment frames.

Q5 Do your nuts meet global standards

Yes. Our products comply with ISO, DIN, GB, and ASTM standards.

English

English  Español

Español  Deutsch

Deutsch

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

+86-137 0583 8919+86-135 8638 0656

+86-137 0583 8919+86-135 8638 0656