How does carbon steel hex nut fasteners external hex nut screw cap grade 4.8 locking screw compare to stainless steel fasteners?

Overview of carbon steel hex nut fasteners external hex nut screw cap grade 4.8 locking screw

Carbon steel hex nut fasteners external hex nut screw cap grade 4.8 locking screw are widely recognized for their combination of strength, cost-effectiveness, and versatility. Manufactured primarily from carbon steel, these fasteners are engineered to maintain consistent mechanical properties across various industrial and construction applications. The grade 4.8 specification ensures a reliable balance between tensile strength and ductility, making it suitable for general-purpose use.

The fundamental advantages of carbon steel hex nuts include easy machinability, compatibility with high-strength bolts, and adaptability to diverse surface treatments that enhance corrosion resistance. These attributes make them a preferred solution for many industrial sectors where performance and economy are both critical.

Mechanical properties and strength comparison

Strength grades and mechanical performance

Carbon steel hex nut fasteners external hex nut screw cap grade 4.8 locking screw are available in multiple strength grades, with grade 4.8 being one of the common industrial grades. The tensile strength and hardness of carbon steel fasteners can be controlled through heat treatment and precise carbon content adjustment. This flexibility allows the production of nuts that are compatible with bolts of varying strength classes, ensuring joint reliability and mechanical integrity.

In contrast, stainless steel fasteners offer higher corrosion resistance but generally have lower tensile strength compared to equivalently sized carbon steel fasteners of grades 8 or 10. Therefore, when load-bearing capacity is a priority, carbon steel hex nuts often provide better performance at a lower cost.

Table: Comparison of key mechanical properties

| Material |

Tensile Strength |

Hardness |

Corrosion Resistance |

Typical Applications |

| Carbon Steel Hex Nut 4.8 |

Medium |

Medium |

Moderate (with coating) |

General industrial, construction |

| Stainless Steel Hex Nut A2 |

Low-Medium |

Medium |

High |

Outdoor, chemical, food industry |

| Carbon Steel Hex Nut 8.8 |

High |

High |

Moderate (with coating) |

Heavy machinery, high-strength joints |

Corrosion resistance and environmental suitability

Carbon steel hex nut fasteners external hex nut screw cap grade 4.8 locking screw can be treated with coatings such as zinc plating, black oxide, or galvanization to enhance corrosion resistance. These surface treatments allow the fasteners to perform reliably in a variety of indoor and outdoor environments, from dry machinery enclosures to moderate outdoor exposure.

By contrast, stainless steel fasteners inherently resist corrosion without additional coatings, making them ideal for chemically aggressive or wet environments. However, this advantage comes with a higher cost and sometimes lower mechanical performance under heavy loads. In most industrial and construction applications, carbon steel fasteners with appropriate coatings are sufficient to balance durability and cost efficiency.

Manufacturing efficiency and machinability

The manufacturing process of carbon steel hex nut fasteners external hex nut screw cap grade 4.8 locking screw is highly efficient due to the material’s excellent ductility and plasticity. Methods such as cold heading, hot forging, and precision turning allow high-volume production while maintaining strict tolerances. Secondary operations, including drilling and threading, can be performed efficiently, enabling tailored solutions based on specific project requirements.

Stainless steel fasteners, while manufacturable at high precision, are generally harder to machine and form. This can result in longer production cycles and higher manufacturing costs. Therefore, from a production perspective, carbon steel fasteners offer a more economical and flexible option for industrial-scale applications.

Applications in industrial and construction sectors

Carbon steel hex nut fasteners external hex nut screw cap grade 4.8 locking screw are widely applied across multiple sectors due to their versatility and strength. They are used in:

- General machinery assembly and maintenance

- Construction structures such as steel frameworks and scaffolding

- Equipment in the chemical and food processing industries (with appropriate surface treatment)

- Medical appliances and precision engineering products

While stainless steel fasteners are preferred in highly corrosive environments or when non-magnetic properties are required, carbon steel fasteners remain the default choice for most applications due to their cost-effectiveness and mechanical reliability.

Advantages of carbon steel hex nuts in practical use

- Cost-effectiveness: Carbon steel fasteners are generally less expensive than stainless steel alternatives, providing a high-performance solution without significant cost penalties.

- Versatility: Available in multiple grades, carbon steel hex nuts can be adapted for a range of strength and load requirements.

- High mechanical reliability: Heat-treated grades resist thread deformation and wear under tightening or vibration.

- Surface adaptability: Coatings and treatments enhance corrosion resistance to meet environmental demands.

By comparison, stainless steel fasteners, while corrosion-resistant, can be less economically viable for large-scale projects where extreme environmental resistance is not a priority.

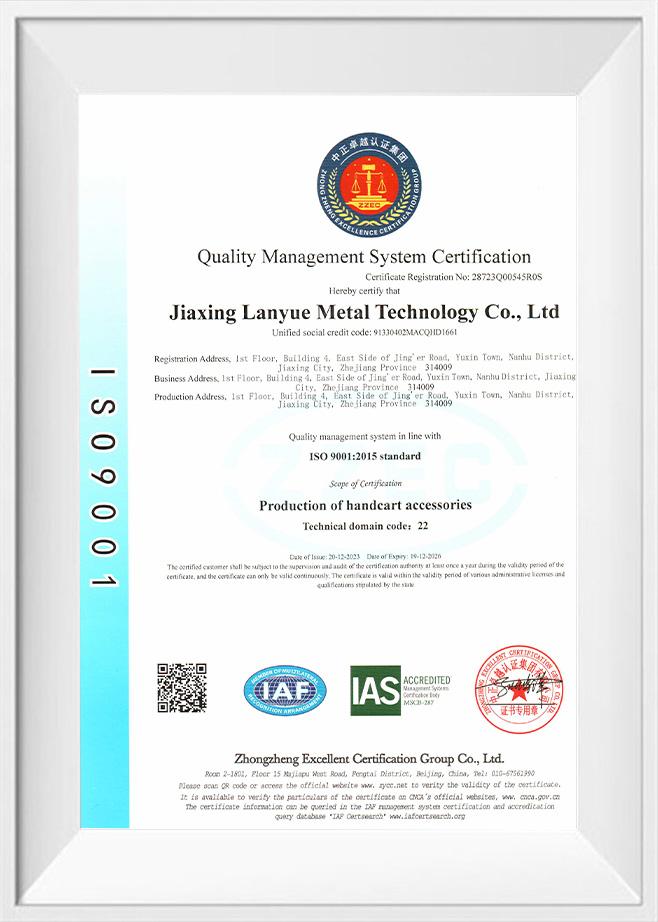

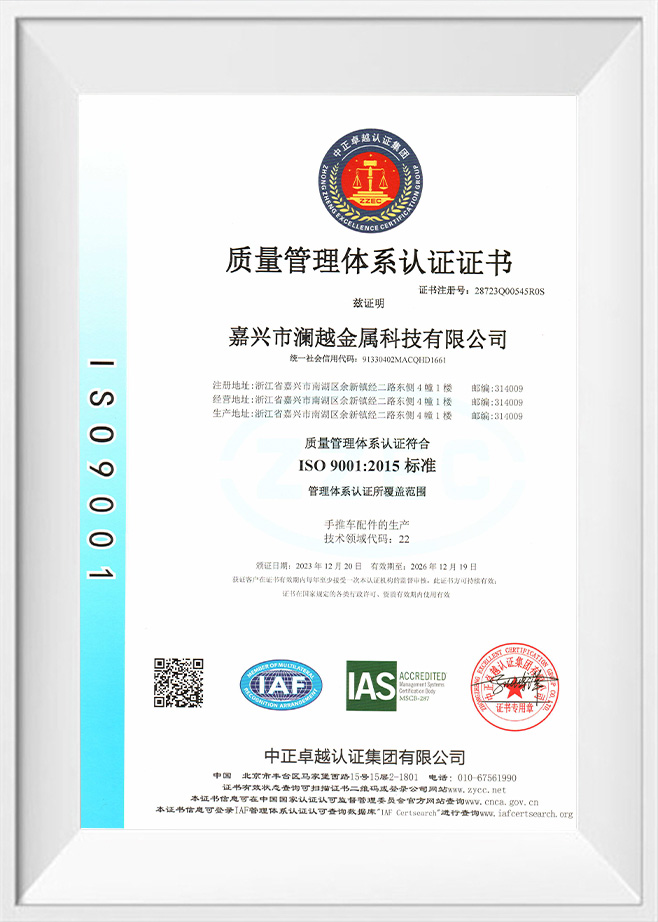

Quality assurance and company standards

Jiaxing Lanyue Metal Technology Co., Ltd. specializes in producing carbon steel hex nut fasteners external hex nut screw cap grade 4.8 locking screw under strict ISO 9001 quality management standards. Each fastener undergoes advanced testing to ensure precision, durability, and reliability, aligning with international standards.

The company’s R&D capabilities and process optimization allow tailored solutions based on customer drawings or samples. Through rigorous inspection systems, Lanyue Metal Technology ensures that every batch of carbon steel hex nuts meets consistent performance metrics suitable for industrial and commercial applications.

Technical considerations when choosing fasteners

When selecting between carbon steel hex nut fasteners external hex nut screw cap grade 4.8 locking screw and stainless steel fasteners, consider the following factors:

- Load capacity requirements: Carbon steel often provides higher tensile strength for the same size.

- Environmental exposure: Stainless steel is preferred in corrosive or wet environments.

- Cost constraints: Carbon steel fasteners with coatings usually cost less than stainless steel.

- Application-specific needs: Non-magnetic or high-conductivity requirements may favor stainless steel.

Ultimately, understanding the specific industrial context and performance requirements will guide the optimal choice.

Summary

In conclusion, carbon steel hex nut fasteners external hex nut screw cap grade 4.8 locking screw provide a balanced solution for industrial and construction applications. They combine cost-effectiveness, mechanical strength, adaptability, and manufacturability. While stainless steel fasteners excel in corrosion resistance and certain specialized applications, carbon steel fasteners are generally preferred when strength, versatility, and economic efficiency are the priority.

By leveraging advanced production techniques, rigorous quality control, and surface treatment options, manufacturers like Jiaxing Lanyue Metal Technology Co., Ltd. ensure that their carbon steel hex nuts meet the demanding requirements of industrial customers worldwide.

FAQs

Q1: Can carbon steel hex nut fasteners external hex nut screw cap grade 4.8 locking screw be used outdoors?

Yes, with proper surface treatments like zinc plating or galvanization, they perform reliably in outdoor environments.

Q2: What industries most commonly use carbon steel hex nut fasteners external hex nut screw cap grade 4.8 locking screw?

They are used in machinery, construction, chemical processing, food machinery, medical appliances, and general-purpose industrial applications.

Q3: How does grade 4.8 affect performance?

Grade 4.8 ensures moderate tensile strength and ductility, suitable for general-purpose applications without requiring extreme load capacity.

Q4: Are carbon steel hex nuts compatible with high-strength bolts?

Yes, carbon steel hex nuts can be manufactured in higher grades and heat-treated to match high-strength bolts, ensuring reliable joint performance.

Q5: How do carbon steel fasteners compare to stainless steel in cost?

Carbon steel fasteners are generally more economical, offering high mechanical reliability at a lower price, while stainless steel excels primarily in corrosion resistance.

English

English  Español

Español  Deutsch

Deutsch

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

+86-137 0583 8919+86-135 8638 0656

+86-137 0583 8919+86-135 8638 0656