Why Are Self-Locking Hex Nuts Critical in Modern Engineering?

In modern mechanical manufacturing and engineering assembly, nuts are critical fasteners whose performance directly affects overall equipment stability and safety. Among them, hex nuts are widely used due to their structural stability, ease of installation, and efficient torque transmission. Especially in industrial scenarios requiring high reliability and long-term operation, the material, design, and additional functionalities of nuts become key considerations. High-performance nuts such as carbon steel nylon anti-loosening anti-slip self-locking hex nuts combine traditional carbon steel with nylon self-locking structures to achieve excellent anti-loosening and anti-slip properties, significantly enhancing fastening safety and service life.

Basic Structure and Function of Hex Nuts

Hex nuts are standard fasteners with a six-sided exterior, designed to mate with bolts and generate clamping force through thread engagement. The hexagonal shape allows wrenches or sockets to apply substantial torque in confined spaces, facilitating assembly and disassembly. Additionally, hex nuts distribute loads evenly, reducing stress concentration and minimizing the risk of breakage or deformation. They are widely applied in load-bearing and precision connection scenarios across industrial machinery, automotive, electronics, and construction, where their performance stability directly influences overall equipment reliability.

Material Selection and Its Impact on Nut Performance

Material selection is a critical factor affecting the mechanical properties and durability of nuts. Carbon steel is widely used for industrial fasteners due to its high strength and good machinability. Through heat treatment and surface finishing, carbon steel nuts can achieve wear resistance, corrosion resistance, and high load capacity. However, in high-vibration or frequent assembly environments, conventional carbon steel nuts are prone to loosening, which can compromise structural safety. Introducing nylon material into the nut design forms carbon steel nylon anti-loosening self-locking hex nuts, where the nylon ring generates friction with the bolt to maintain locking effect, greatly improving anti-loosening performance. This hybrid design combines the strength of carbon steel with the frictional protection of nylon, representing a key trend in industrial locking fasteners.

Anti-Loosening and Anti-Slip Technologies

Nuts may loosen under vibration, impact, or thermal expansion and contraction, leading to structural failure. To enhance nut reliability, several technical approaches are applied:

- Self-locking structures: Nylon insert locking or metal locking elements generate continuous friction with the bolt, preventing loosening in vibration-prone environments.

- Anti-slip design: Surface or contact area modifications increase friction, stabilizing the nut under high vibration or torque.

- Special surface treatments: Zinc plating, nickel plating, or protective coatings extend service life while maintaining fastening force, preventing loosening due to corrosion.

In high-demand industrial applications—such as machinery, automated production lines, and transportation equipment—the use of carbon steel nylon anti-loosening anti-slip self-locking hex nuts effectively reduces maintenance costs and equipment downtime.

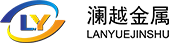

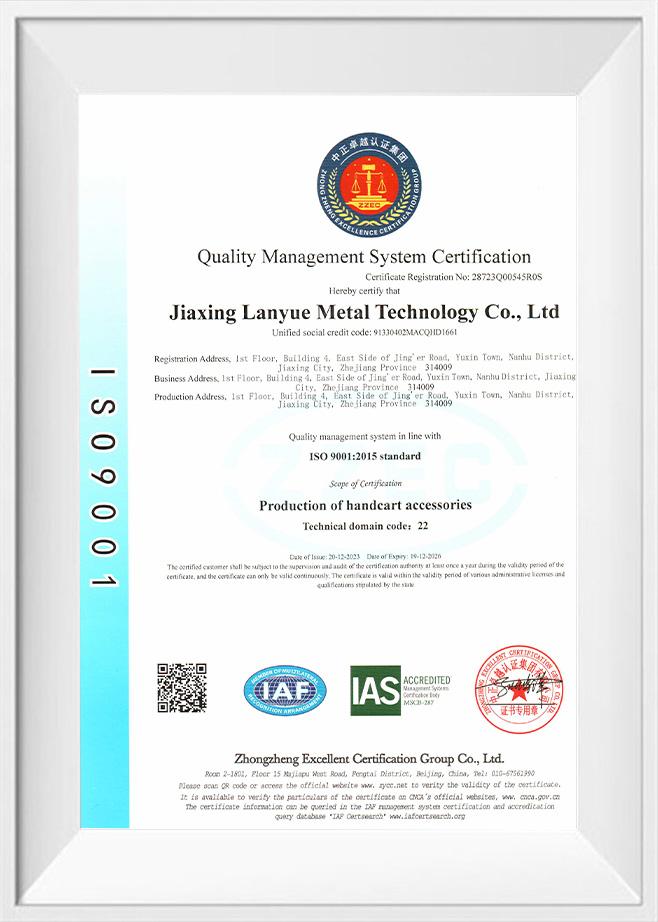

Precision Manufacturing and Quality Control

The reliability of high-performance hex nuts depends on precision manufacturing and strict quality management. Thread accuracy, dimensional tolerance, and proper installation of nylon inserts directly affect fastening performance. Jiaxing Lanyue Metal Technology Co., Ltd. specializes in the research, development, production, and sales of precision metal and engineering plastic products. By establishing and implementing a comprehensive ISO 9001 quality management system, the company ensures that every product meets international standards. Advanced testing equipment and rigorous production processes allow full inspection of material properties, hardness, torque performance, and self-locking functionality, guaranteeing stable and reliable performance across diverse industrial environments.

Application Fields and Customization Needs

Hex nuts exhibit broad adaptability in industrial applications, spanning machinery manufacturing, automotive, wind power equipment, rail transit, household appliances, and construction. Different scenarios impose specific requirements on nut performance:

- High-vibration environments require superior anti-loosening and durability;

- High-temperature or corrosive environments require materials with oxidation resistance and corrosion protection;

- Precision assembly environments require high dimensional accuracy and consistent torque performance.

To meet these needs, Jiaxing Lanyue Metal Technology Co., Ltd. provides customized solutions based on client drawings or samples, offering tailored design, material selection, and precision manufacturing to achieve precise functional performance. The company’s large-scale production capacity and fast delivery system ensure stable output and timely fulfillment for both small and large orders worldwide.

Conclusion

In conclusion, hex nuts are fundamental yet essential fasteners whose performance relies on material choice, structural design, precision manufacturing, and strict quality control. High-performance nuts such as carbon steel nylon anti-loosening anti-slip self-locking hex nuts combine carbon steel strength with nylon self-locking features to provide both durability and reliability.

English

English  Español

Español  Deutsch

Deutsch

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

+86-137 0583 8919+86-135 8638 0656

+86-137 0583 8919+86-135 8638 0656