What Makes Galvanized Fasteners Essential for Modern Manufacturing?

In modern industrial manufacturing and construction, carbon steel fasteners play a crucial role in ensuring structural integrity, operational safety, and long-term durability. Understanding the material properties, galvanization processes, mechanical characteristics, and application-specific requirements of these components is critical for engineers, procurement specialists, and quality managers.

Material Properties and Selection Criteria

The base material for these fasteners, carbon steel, is chosen for its high tensile strength, machinability, and cost-effectiveness. The selection of the carbon steel grade is influenced by the required mechanical performance, corrosion resistance, and operational environment. Commonly used grades include medium to high-carbon steels, which offer a balance between hardness and ductility.

| Property |

Importance |

Typical Range for Hex Head Screws |

| Tensile Strength |

Determines load-bearing capability |

400–800 MPa |

| Hardness |

Influences wear resistance and thread longevity |

150–250 HB |

| Ductility |

Ensures resistance to brittle fracture |

10–20% elongation |

| Corrosion Resistance |

Essential for outdoor or harsh environments |

Dependent on galvanization thickness |

For extended half-thread bolts, the same material considerations apply, with an emphasis on partially threaded sections that require uniform tensile distribution along the shank. The material must balance machinability for threading with mechanical robustness for structural applications.

Galvanization Process and Surface Protection

Galvanization is a key process for carbon steel fasteners to enhance corrosion resistance. The zinc coating protects the steel from oxidation, extending the service life of the fastener in both indoor and outdoor environments. There are several galvanization methods, including hot-dip galvanizing and electro-galvanizing.

| Galvanization Method |

Characteristics |

Applications |

| Hot-Dip Galvanizing |

Thick, durable coating, good for harsh environments |

Construction, marine, heavy machinery |

| Electro-Galvanizing |

Thinner, smoother coating, precise control |

Electronics, light machinery, precision applications |

| Zinc Alloy Plating |

Enhanced aesthetic and moderate corrosion resistance |

Automotive interiors, decorative fixtures |

The choice between these methods depends on environmental exposure, expected service life, and mechanical stress on the fastener. For high-performance extended half-thread bolts, galvanization uniformity is crucial to avoid weakening the unthreaded portion of the shank.

Mechanical Performance and Standards

The mechanical performance of galvanized carbon steel hex head screws is measured through metrics such as tensile strength, shear resistance, and torque capacity. Adherence to international standards ensures consistency in production and reliability in application.

Key standards include:

- ISO 898-1 for mechanical properties of fasteners

- DIN 933 for hexagon head bolts with full or partial threading

- ASTM A325/A490 for high-strength structural bolts

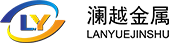

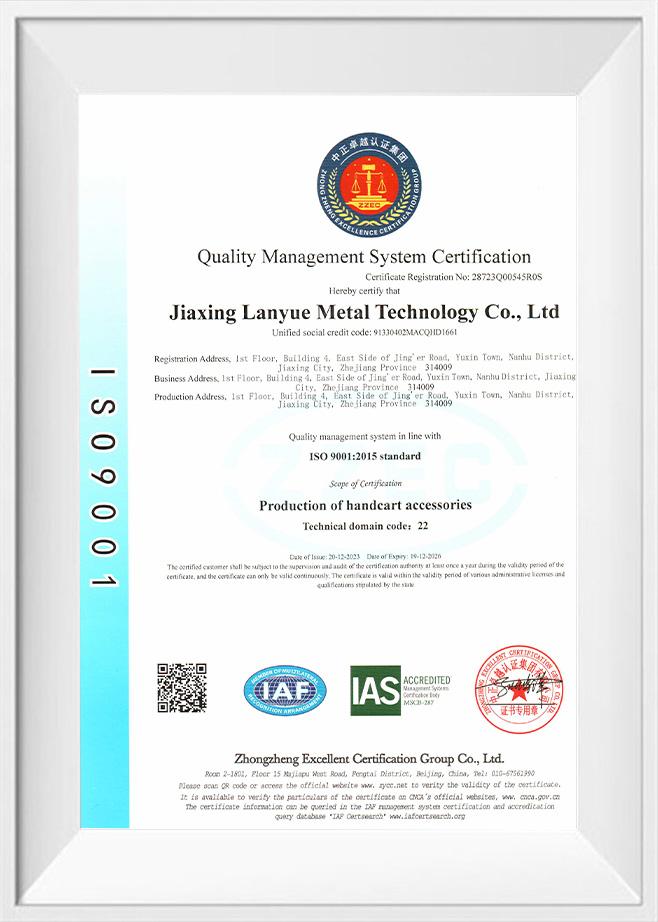

Ensuring compliance with these standards is essential for both safety and performance. Jiaxing Lanyue Metal Technology Co., Ltd. strictly adheres to the ISO 9001 quality management system, ensuring that every batch of fasteners meets or exceeds these international standards.

Design and Application Considerations

The selection of hexagonal head screws depends on assembly requirements, load distribution, and the installation environment. Hex head screws are favored for their ease of installation with standard wrenches and their ability to handle high torque. Extended half-thread bolts offer improved tensile strength along the shank, making them ideal for components subjected to combined tension and shear forces.

| Fastener Type |

Advantages |

Common Industrial Use |

| Galvanized Hex Head Screw |

High torque capacity, corrosion resistance, versatile |

Machinery assembly, structural connections |

| Extended Half-Thread Bolt |

Uniform load distribution, enhanced fatigue resistance |

Heavy machinery, automotive, construction |

Proper thread engagement, head geometry, and material compatibility are critical for avoiding stress concentrations, thread stripping, and premature failure.

Manufacturing Excellence and Quality Control

High-quality production of these fasteners requires advanced machinery, precision machining, and stringent inspection. Jiaxing Lanyue Metal Technology Co., Ltd. leverages its more than a decade of experience to ensure:

- High Quality – Every product undergoes strict testing, ensuring precision and durability.

- Fast Shipping – Efficient production and flexible scheduling ensure on-time delivery globally.

- Customization Service – Tailored solutions based on customer drawings or samples.

- Large Capacity – Advanced production lines support both small and large orders.

- Rich Experience – Over 10 years of OEM manufacturing expertise.

- Quality Approval – Compliance with ISO9001, CE, and other certifications.

- R&D Innovation – Strong ODM & OEM capabilities with multiple patents.

- Comprehensive Service – Full after-sales support for custom designs.

Application-Specific Recommendations

Selecting the right fastener requires consideration of environmental exposure, mechanical load, and assembly method:

- For outdoor construction or marine applications, hot-dip galvanized hex head screws offer superior corrosion resistance.

- In high-strength structural assemblies, extended half-thread bolts provide uniform stress distribution along the shank.

- For precision machinery, electro-galvanized screws minimize surface roughness while maintaining adequate protection.

Attention to installation torque, lubrication, and thread engagement is essential to maintain long-term reliability and performance.

Conclusion

The professional selection, production, and application of carbon steel fasteners require a deep understanding of materials science, galvanizing processes, mechanical properties, and industry standards. By integrating rigorous quality management, innovative manufacturing, and customer-centric service, Jiaxing Lanyue Metal Technology Co., Ltd. ensures that its industrial fasteners meet the ever-changing demands of modern engineering applications.

English

English  Español

Español  Deutsch

Deutsch

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

+86-137 0583 8919+86-135 8638 0656

+86-137 0583 8919+86-135 8638 0656