What factors make carbon steel fasteners indispensable in modern industrial applications?

In mechanical manufacturing, construction, automotive industries, and energy equipment, fasteners are critical components that ensure structural stability and optimize mechanical performance. Among these, carbon steel fasteners are widely adopted due to their exceptional mechanical properties, processing versatility, and cost efficiency. Carbon steel, as a material for fasteners, offers high strength, wear resistance, and excellent machinability, making it suitable for a variety of industrial applications. From standard carbon steel hex bolts to customized extended screws, carbon steel fasteners demonstrate remarkable adaptability in engineering design.

Material Properties and Engineering Advantages of Carbon Steel Fasteners

Carbon steel fasteners are typically made from medium-carbon or high-carbon steel, with heat treatment processes applied to further enhance strength and hardness. In mechanical connections, high-strength carbon steel fasteners can effectively withstand tensile, shear, and torsional loads, ensuring long-term structural stability. For instance, carbon steel hex bolts and carbon steel hex head screws maintain precise torque performance under high loads, reducing the risk of loosening and structural failure.

Additionally, carbon steel fasteners exhibit excellent machinability and surface treatment adaptability. Depending on the application environment, surface coatings such as zinc plating, nickel plating, hot-dip galvanizing, or black oxide can enhance corrosion resistance and wear performance. This allows carbon steel fasteners to perform reliably in indoor and outdoor, dry or humid environments, meeting international standards for strength and durability.

Types of Carbon Steel Fasteners and Industrial Applications

-

Carbon Steel Hex Bolts

Carbon steel hex bolts are among the most commonly used mechanical fasteners, widely applied in equipment assembly, machinery frames, and construction structures. Their hexagonal head design allows easy installation using wrenches or sockets, providing high torque output and ensuring even load distribution. With precise threading and surface treatment, carbon steel hex bolts maintain stable performance under high stress conditions.

-

Carbon Steel Hex Head Screws

Similar to hex bolts, carbon steel hex head screws are typically used for metal-to-metal connections or applications requiring frequent assembly and disassembly. Their thread design ensures stability under vibration and impact loads, and various lengths and diameters allow for diverse industrial applications.

-

Extended Screws

Extended screws are essential in specialized structures or deep-hole installations, enabling connections that standard fasteners cannot achieve. In machinery, aerospace structures, and large-scale industrial assemblies, extended screws ensure reliable long-length fastening while maintaining the durability and stability of standard carbon steel fasteners.

Manufacturing and Quality Control of Carbon Steel Fasteners

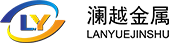

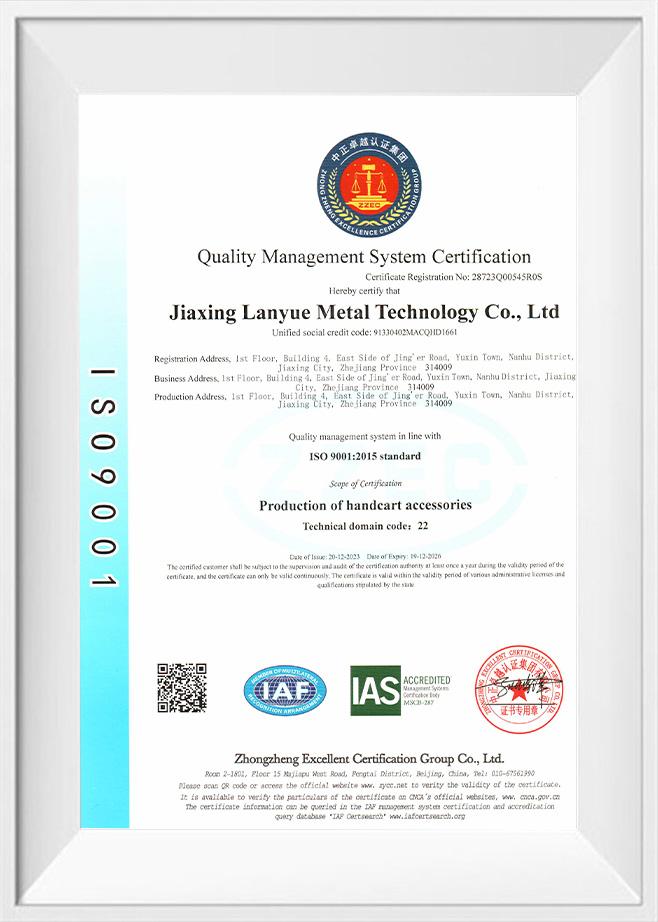

Producing high-quality carbon steel fasteners relies not only on material selection but also on strict manufacturing control and precise inspection. Jiaxing Lanyue Metal Technology Co., Ltd. specializes in the research, development, production, and sales of precision metal and engineering plastic products, implementing a comprehensive ISO 9001 quality management system. From raw material inspection, heat treatment, machining, to surface finishing, every step undergoes rigorous testing to ensure each carbon steel fastener meets international standards for precision and durability.

Key quality indicators include thread accuracy, bolt hardness, torque-bearing capacity, and surface corrosion resistance. The reliability of carbon steel fasteners directly impacts equipment safety and service life. Scientific production management and precise inspection methods are therefore crucial to ensuring high-performance fasteners.

Design and Selection Considerations in Industrial Applications

When designing fastened connections, engineers must consider bolt strength grades, thread types, surface treatments, and environmental conditions. Carbon steel fasteners, due to their material hardness and adaptability, are suitable for various load types and installation environments. Selecting the appropriate carbon steel hex bolts, hex head screws, or extended screws can significantly improve structural stability and maintenance efficiency.

Custom fasteners are increasingly sought after by industrial clients. Jiaxing Lanyue Metal Technology Co., Ltd. provides tailored solutions based on drawings or samples, offering design optimization, material selection, and surface treatment customization. This flexibility enhances functional adaptability and operational efficiency across industrial applications.

Logistics and Supply Advantages

In industrial production, timely supply and large-scale production capacity are equally important. Jiaxing Lanyue Metal Technology Co., Ltd., equipped with advanced production lines and efficient management systems, ensures stable output for both small and large orders, meeting urgent client demands. Fast delivery, quality assurance, and flexible customization give the company a significant competitive advantage in the global fastener market.

Conclusion

Carbon steel fasteners, with their high strength, wear resistance, machinability, and cost-effectiveness, are indispensable components in industrial applications. From standard carbon steel hex bolts and hex head screws to specialized extended screws, these fasteners play a critical role in structural stability and long-term reliability. Through rigorous production management and ISO 9001 quality assurance, Jiaxing Lanyue Metal Technology Co., Ltd. provides precision, customizable carbon steel fasteners to meet diverse industrial needs worldwide.

English

English  Español

Español  Deutsch

Deutsch

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

+86-137 0583 8919+86-135 8638 0656

+86-137 0583 8919+86-135 8638 0656