Industry Insights on 8.8 Grade Galvanized Carbon Steel Hexagonal Screws

8.8 Grade galvanized carbon steel hexagonal screws, also known as high strength extended half thread bolts, play an essential role in machinery manufacturing, equipment installation, steel structures, automotive engineering and many other industrial applications. As industrial systems move toward higher load capacity, longer service life and enhanced safety, the demand for high strength fasteners continues to increase.

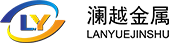

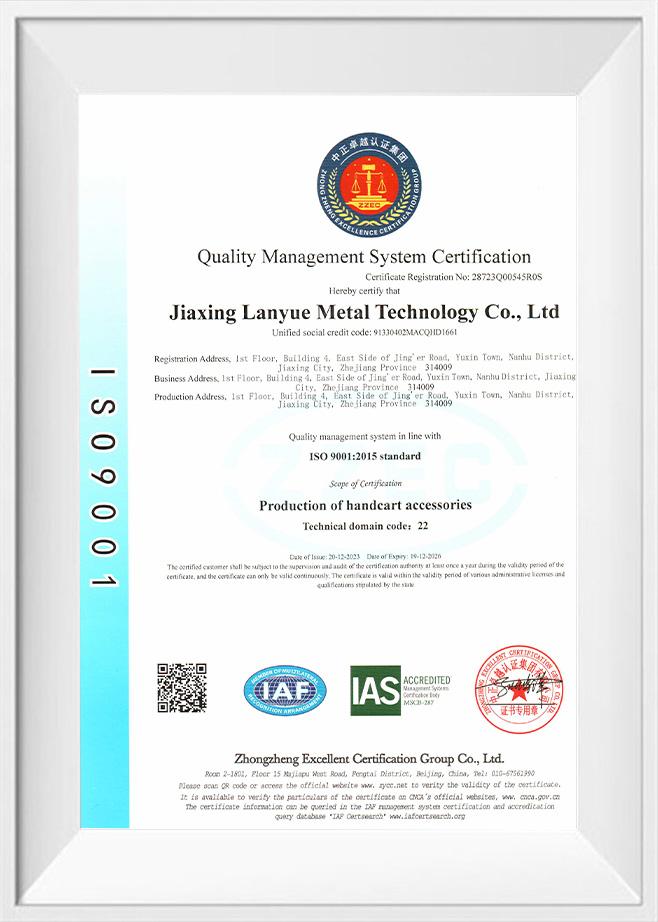

As a professional manufacturer, Jiaxing Lanyue Metal Technology Co., Ltd. provides stable, precise and durable high strength carbon steel fasteners to global industrial customers. Located in Jiaxing, Zhejiang, a major manufacturing region in the Yangtze River Delta, the company operates under a comprehensive ISO 9001 quality management system and focuses on innovation driven metal and plastic precision manufacturing.

Main Features of 8.8 Grade Galvanized Carbon Steel Hexagonal Screws

High Strength Performance

Grade 8.8 screws are produced from medium carbon steel and heat treated to achieve strong mechanical properties. Their key performance characteristics include:

- Tensile strength: 800 MPa

- Yield strength: not less than 640 MPa

- Suitable for applications with heavy load, vibration or impact

Compared with lower strength levels such as 4.8 or 6.8, grade 8.8 screws are ideal for critical components and heavy duty working conditions.

Enhanced Corrosion Resistance with Zinc Plating

The zinc coating forms an oxidation resistant protective layer, providing excellent corrosion resistance. This treatment is suitable for outdoor equipment, humid environments and areas with mild chemical exposure. It effectively extends the service life of components and reduces maintenance costs.

Hexagon Head Structure

The hexagonal head design provides better installation and tightening performance. It supports the use of manual tools and power tools, ensuring stable torque transmission. This structure is particularly useful in limited installation spaces that require strong fastening strength.

Extended Half Thread Design

The extended half thread structure offers improved shear strength due to the unthreaded section. It also increases the contact surface between components, enhancing overall stability. This makes it suitable for equipment frames, heavy machinery and precision assembly applications.

Typical Application Industries

| Industry |

Application |

Advantages |

| Machinery Manufacturing |

Motors, frames, component mounting |

High load support and vibration resistance |

| Steel Structure Engineering |

Bridges, building frames |

Stable strength and outdoor adaptability |

| Automotive Industry |

Chassis, frames, suspension systems |

Impact resistance and long service life |

| Industrial Equipment |

Mounting and support structures |

Easy installation and strong load capacity |

| New Energy Equipment |

Wind power devices, photovoltaic supports |

Corrosion resistance and secure fastening |

Why Choose Lanyue Metal Technology

As a leading manufacturer, Jiaxing Lanyue Metal Technology Co., Ltd. offers complete production capabilities from raw material control to tooling development and final inspection.

- ISO 9001 quality management system ensuring stable product standards

- Advanced cold heading and heat treatment processes

- OEM support and customized production according to DIN, ISO and GB standards

- Fast delivery supported by the strong supply chain of Jiaxing fastener industry

Sample Product Specifications

| Specification Type |

Available Options |

| Material |

Carbon steel such as C35 or C45 |

| Strength Grade |

8.8 |

| Surface Treatment |

Zinc plated, hot dip galvanized, dacromet, black oxide |

| Length Range |

20mm to 300mm or customized |

| Thread Type |

Half thread or full thread |

| Standards |

DIN 931, DIN 933, ISO 4014, ISO 4017 |

Frequently Asked Questions

Is an 8.8 grade galvanized screw suitable for outdoor use

Yes. The zinc coating provides effective protection against moisture and oxidation, making it suitable for general outdoor applications. For environments with high corrosion levels, hot dip galvanizing or dacromet coating is recommended.

What is the difference between half thread and full thread bolts

Half thread bolts offer higher shear strength and better positioning for structural assembly, while full thread bolts provide flexible adjustment and better fastening for components requiring fine positioning.

Can the company provide OEM or customized services

Yes. The company supports drawing based manufacturing, customized materials, customized coating options and large scale production.

How do you ensure stable quality

The company uses an ISO 9001 quality management system, automatic inspection equipment, metallographic analysis, salt spray testing and tensile strength testing to ensure consistent quality.

Are samples available

Yes, samples can be provided for testing before mass production.

English

English  Español

Español  Deutsch

Deutsch

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

+86-137 0583 8919+86-135 8638 0656

+86-137 0583 8919+86-135 8638 0656