How do hand-pulled trolleys compare with motorized transporters?

Introduction to material handling equipment

In modern industrial and commercial environments, the efficiency of heavy-duty steel trolley, cargo trolley, transporter, household flatbed trolley, portable trailer, folding small trolley, hand-pulled trolley plays a crucial role in streamlining operations. Material handling solutions vary significantly, with manual hand-pulled trolleys and motorized transporters representing two primary categories. Selecting the appropriate solution depends on the load requirements, operational environment, and workflow efficiency.

While motorized transporters offer automation and reduced physical labor, hand-pulled trolleys provide flexibility, portability, and low operational costs. Understanding the differences in design, performance, and applications can help buyers make informed decisions.

Structural and material differences

Heavy-duty steel trolley, cargo trolley, and transporter designs often feature robust frames made of high-quality cold-rolled steel plates or high-strength steel. These materials ensure strong load-bearing capacity, longevity, and resistance to deformation. In contrast, hand-pulled trolleys and folding small trolleys typically prioritize portability while maintaining sufficient strength to carry moderate loads.

Household flatbed trolleys and portable trailers often incorporate lightweight yet durable materials to ensure easy maneuverability in domestic and semi-industrial settings. Key structural elements include anti-slip surfaces, guardrails, and ergonomic handles, all contributing to operational safety. The presence of braked or silent casters enhances stability and minimizes the risk of accidents, especially when transporting heavy or delicate items.

Operational efficiency and ergonomics

When comparing hand-pulled trolleys to motorized transporters, ergonomics and labor requirements become central considerations. Hand-pulled trolleys allow operators to control the pace and direction, requiring minimal training and energy for moderate loads. Silent casters reduce noise levels, making these trolleys suitable for office, laboratory, or library environments where quiet operation is essential.

Motorized transporters, on the other hand, provide consistent movement regardless of load weight, increasing efficiency in large-scale warehouses or factories. They reduce physical strain but require maintenance, energy input, and adherence to safety protocols.

Customization and versatility

The versatility of heavy-duty steel trolley, cargo trolley, transporter, household flatbed trolley, portable trailer, folding small trolley, hand-pulled trolley lies in their customizable designs. Multi-layer shelving, adjustable platform heights, and modular components allow users to tailor solutions to specific applications. For instance, folding small trolleys can be compacted for storage, while portable trailers can accommodate irregular or bulky loads.

Jiaxing Lanyue Metal Technology Co., Ltd. provides tailored solutions based on drawings or samples, allowing precise adaptation to industry requirements. Their approach ensures that trolleys meet both operational demands and ergonomic standards.

Applications across industries

Heavy-duty steel trolley, cargo trolley, transporter, household flatbed trolley, portable trailer, folding small trolley, hand-pulled trolley serve diverse industries:

- Warehouses and logistics: These trolleys assist in cargo transshipment, product distribution, and handling of boxes and bagged items. Motorized transporters excel in high-volume operations, whereas hand-pulled trolleys offer flexibility in compact spaces.

- Production workshops and factories: In electronics, mold, and plastics factories, trolleys transport raw materials, semi-finished products, and tools. Multi-layer designs and adjustable shelving enhance organization and operational efficiency.

- Offices and libraries: Household flatbed trolleys and document carts facilitate the movement of files, books, and office supplies. Quiet operation and smooth maneuverability are critical.

- Laboratories and healthcare facilities: Trolleys support transportation of instruments, pharmaceuticals, and laboratory equipment. Corrosion-resistant materials and easy-to-clean surfaces maintain hygiene and safety standards.

- Hospitality and food service: Hotel kitchens and restaurants benefit from trolleys designed for food transfer and tableware recycling. Smooth surfaces and anti-slip casters improve safety and cleaning efficiency.

- Home and gardening: Lightweight folding small trolleys and hand-pulled trolleys are ideal for moving small items, gardening materials, or household tools. Their quiet operation and floor protection are important in domestic environments.

Safety and reliability considerations

Safety is paramount in material handling. Heavy-duty steel trolley, cargo trolley, transporter, household flatbed trolley, portable trailer, folding small trolley, hand-pulled trolley feature:

- Anti-slip surfaces and guardrails to prevent accidental drops.

- Braked or silent casters to stabilize loads and minimize operational noise.

- Durable construction ensuring the trolley withstands repeated use without deformation.

These features reduce the risk of injury to personnel and protect transported goods, whether in industrial or home environments.

Maintenance and durability

Routine maintenance affects performance and longevity. Hand-pulled trolleys require minimal upkeep but should be regularly inspected for wheel alignment, caster functionality, and structural integrity. Heavy-duty trolleys and motorized transporters benefit from periodic lubrication, surface inspection, and load testing.

The application of electrostatic powder coating, seamless welding, and corrosion-resistant finishes ensures heavy-duty steel trolley, cargo trolley, transporter, household flatbed trolley, portable trailer, folding small trolley, hand-pulled trolley maintain appearance, structural strength, and resistance to environmental factors.

Performance comparison: hand-pulled vs motorized transporters

| Feature |

Hand-pulled trolleys |

Motorized transporters |

| Load capacity |

Moderate |

High |

| Operational noise |

Low |

Variable, often higher |

| Flexibility |

High, can navigate tight spaces |

Limited by size and turning radius |

| Energy requirement |

Manual |

Electric or fuel-powered |

| Maintenance |

Minimal |

Requires scheduled maintenance and charging/fueling |

| Cost |

Lower initial investment |

Higher initial cost and operational expense |

| Application environment |

Offices, small factories, libraries, home |

Warehouses, large-scale production, logistics centers |

This comparison highlights that hand-pulled trolleys are ideal for smaller-scale operations requiring flexibility and quiet operation, whereas motorized transporters excel in high-volume, repetitive tasks demanding speed and minimal labor input.

Advantages of Jiaxing Lanyue Metal Technology trolleys

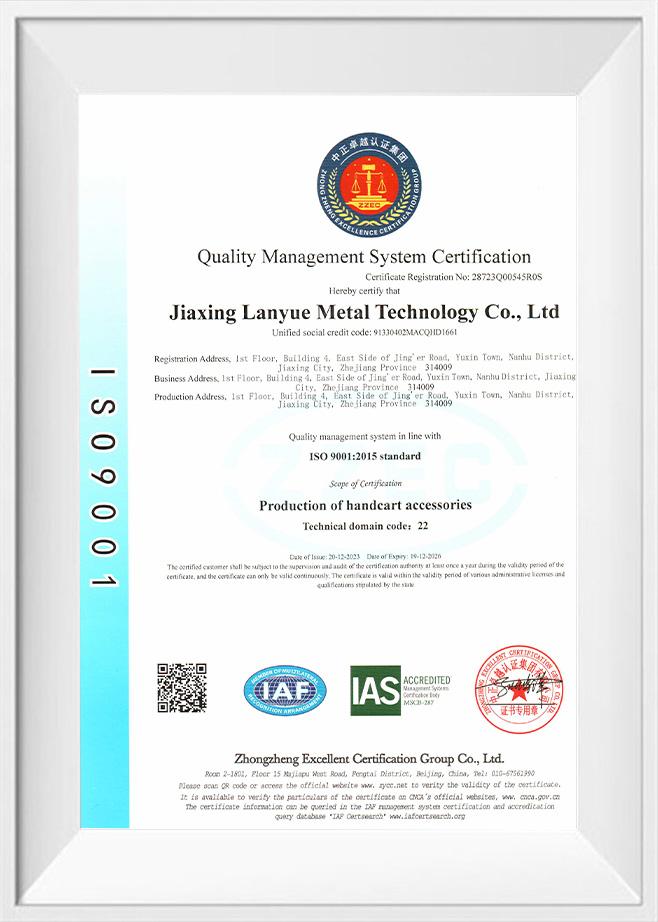

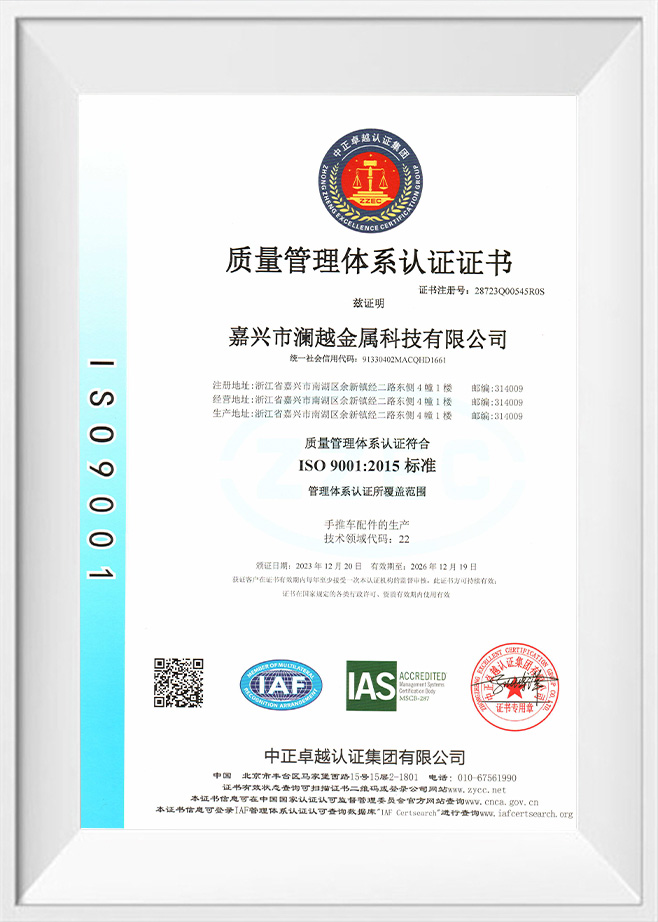

Jiaxing Lanyue Metal Technology Co., Ltd. emphasizes:

- Precision and durability through ISO 9001-compliant manufacturing.

- Tailored solutions using customer drawings or samples.

- Innovative design to enhance ergonomics and operational efficiency.

- Wide applicability across industries, from warehouses to laboratories.

Their trolleys integrate high-strength steel construction, anti-slip surfaces, silent casters, and customizable designs to meet diverse requirements.

Environmental and operational considerations

Selecting the right trolley involves considering floor types, maneuverability, and environmental conditions. Hand-pulled trolleys are particularly suitable for environments where quiet operation is critical, such as libraries, offices, and hospitals. Corrosion-resistant finishes and easy-to-clean surfaces make these trolleys practical for food service, laboratories, and outdoor gardening tasks.

Motorized transporters may consume more energy but reduce operator fatigue and increase throughput in large-scale operations. Understanding workflow patterns, load characteristics, and spatial constraints ensures optimal selection of the trolley type.

Conclusion

Heavy-duty steel trolley, cargo trolley, transporter, household flatbed trolley, portable trailer, folding small trolley, hand-pulled trolley remain indispensable tools in material handling. While hand-pulled trolleys excel in flexibility, quiet operation, and cost-effectiveness, motorized transporters are suitable for high-volume industrial settings. Evaluating load capacity, ergonomics, safety, and operational efficiency allows buyers to choose the best solution for their specific needs.

By integrating advanced manufacturing standards, robust materials, and customizable designs, Jiaxing Lanyue Metal Technology Co., Ltd. ensures that each trolley offers precision, reliability, and versatile application across industries.

FAQs

Q1: What is the maximum load capacity of a heavy-duty steel trolley?

A1: Load capacities vary by design, typically ranging from 200 kg to over 1,000 kg, depending on size, material, and construction quality.

Q2: Can folding small trolleys be used outdoors?

A2: Yes, provided the surface is relatively even. Many folding small trolleys feature durable wheels suitable for garden paths or pavements.

Q3: How do I maintain a hand-pulled trolley for long-term use?

A3: Regularly check wheel alignment, lubricate moving parts, inspect casters, and clean surfaces to prevent corrosion.

Q4: Are portable trailers suitable for industrial warehouse use?

A4: Yes, portable trailers can handle moderate loads and are particularly useful for transporting bulky or irregular items in warehouses.

Q5: What industries commonly use household flatbed trolleys?

A5: Offices, libraries, healthcare facilities, hotels, and domestic environments often rely on household flatbed trolleys for transporting small to medium loads efficiently.

English

English  Español

Español  Deutsch

Deutsch

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

+86-137 0583 8919+86-135 8638 0656

+86-137 0583 8919+86-135 8638 0656