1. The Foundation of Heavy Loads: Steel Selection and Structural Mechanics Design for Heavy-Duty Steel Plate Hand Carts

The load-bearing capacity and durability of a hand cart are fundamentally determined by its material selection and structural design. This article delves into the key steels used in manufacturing Heavy-Duty Steel Plate Hand Carts, such as Q235 and manganese steel, and analyzes the mechanical structural design of the frame, including the layout of reinforcing ribs, welding processes, and stress distribution principles. These factors collectively determine the product's final safety factor and service life.

Key Parameters and Material Properties

- Q235 Steel:

- Yield Strength: ≥ 235 MPa

- Features: Good toughness and weldability, cost-effective, suitable for medium-duty hand carts.

- Manganese Steel:

- Tensile Strength: ≥ 635 MPa

- Features: Extremely high wear resistance and impact resistance, suitable for extra-heavy loads and harsh conditions.

- Plate Thickness: Typically ranges from 2.5mm to 5.0mm, with thickness directly proportional to load capacity.

- Welding Process: CO2 gas shielded arc welding, ensuring weld strength is no less than 90% of the base material.

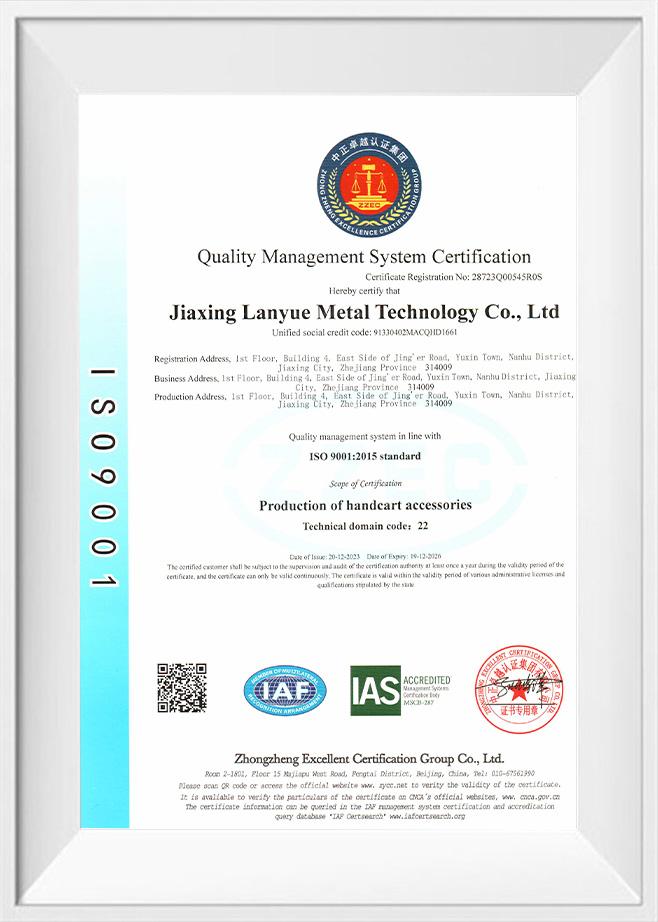

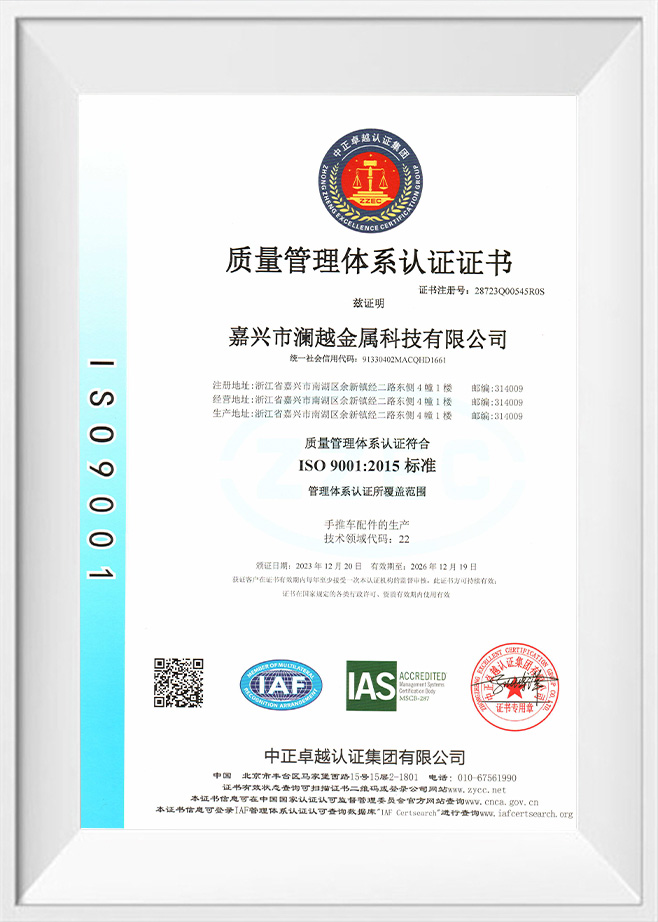

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

As a leading enterprise specializing in the research, development, and production of precision metal products, Jiaxing Lanyue Metal Technology Co., Ltd. possesses a profound understanding of material science and structural mechanics. We strictly adhere to the ISO 9001 quality management system, exercising strict control over every stage from raw material procurement to final product delivery. We are committed to continuously optimizing product structures through technological innovation, ensuring that every heavy-duty steel plate hand cart possesses excellent load-bearing capacity and structural stability, earning customer trust with superior quality.

2. From Warehouse to Home: Selection Differences and Application Analysis of Freight Hand Trucks and Home Use Flatbed Trailers

Although functionally similar, freight hand trucks for commercial logistics and portable flatbed carts designed for home use exhibit significant differences in design philosophy, functional focus, and performance parameters. This article compares and analyzes these two product categories in terms of load capacity, wheel configuration, folding mechanisms, and ease of operation to help users make informed choices based on their specific scenarios.

Key Parameter Comparison

| Feature |

Freight Hand Truck |

Home Use Flatbed Trailer |

| Rated Load |

300 - 800 kg |

100 - 300 kg |

| Wheel Type |

Heavy-duty PU or iron core wheels, diameter ≥200mm |

Lightweight PU or rubber wheels, diameter ≤125mm |

| Deck Material |

Thickened steel plate, focus on durability |

Standard steel or aluminum alloy, focus on portability |

| Folding Design |

Focuses on structural stability, simpler mechanism |

One-touch quick fold, focuses on compact storage |

| Main Applications |

Warehouses, logistics, construction sites |

Supermarket shopping, home moving, gardening |

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

Located in the core manufacturing region of the Yangtze River Delta, Jiaxing Lanyue Metal Technology Co., Ltd. is committed to providing diversified, high-quality component solutions to industrial customers worldwide. We deeply understand the differentiated needs of various application scenarios, which is why our product line covers a full range from professional-grade freight hand trucks to lightweight home-use flatbed trailers. Through modular design and lean production, we can flexibly respond to market demands and create shared value with partners in different fields.

3. The Core of Mobility: An In-depth Look at the Wheel System of Heavy-Duty Hand Carts—Materials, Bearings, and Load Capacity

Wheels are the most critical functional components of a hand cart, and their performance directly determines user experience and transport efficiency. This article provides a detailed analysis of the composition of a heavy-duty hand cart's wheel system, including wheel surface materials (PU, rubber, nylon), bearing types (ball bearings, needle bearings), and caster frame design. It also explains how to select the most suitable wheel system based on ground conditions, load, and noise requirements, supported by specific parameters.

Key Wheel System Parameters

- PU (Polyurethane) Wheels:

- Advantages: Quiet, wear-resistant, non-marking on floors.

- Application: Indoor use, smooth surfaces, noise-sensitive environments.

- Solid Rubber Wheels:

- Advantages: Good shock absorption, strong adaptability, maintenance-free.

- Application: Outdoor use, uneven terrain, general loads.

- Heavy-Duty Iron Core Wheels:

- Advantages: Extremely high load capacity, super durable.

- Application: Extra-heavy loads, harsh conditions (e.g., construction sites, gravel roads).

- Bearing Precision: Utilizes precision ball bearings to ensure flexible rotation and low starting resistance.

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

Jiaxing Lanyue Metal Technology Co., Ltd. consistently adheres to the philosophy of "Striving for Excellence, Innovating for the Future," extending technological innovation to every single component. We not only design and manufacture the main structure of the hand cart but also conduct rigorous selection and testing of the wheel system. We collaborate with top-tier wheel suppliers to ensure every wheel meets the requirements of its designed operating conditions, thereby enhancing the overall performance of the machine and providing users with a smooth, reliable, and durable mobile experience.

4. Balancing Portability and Strength: The Design Principles and Manufacturing Processes of Folding Hand-Pulled Carts

The core challenge in designing a folding hand-pulled cart lies in achieving a lightweight, compact fold while guaranteeing structural strength and load stability when deployed. This article analyzes the common design principles of folding hand-pulled carts (such as cross-support structures and rotary locking mechanisms) and introduces the key manufacturing processes required to achieve this balance, including precision stamping, bending, and assembly techniques.

Key Design and Process Parameters

- Folding Ratio: The ratio of folded volume to deployed volume; excellent designs can achieve 1:4 or higher.

- Locking Mechanism: Must have a reliable locking device to prevent accidental folding during use, typically using spring pins or snap-lock designs.

- Joint Treatment: Folding joints are stress concentration points and require reinforcement or the use of wear-resistant bushings.

- Assembly Precision: The assembly tolerance of key connection points must be controlled within ±0.5mm to ensure smooth folding and structural stability.

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

Jiaxing Lanyue Metal Technology Co., Ltd. possesses comprehensive precision metal manufacturing capabilities, making us an ideal partner for solving complex design challenges. In the manufacturing of folding hand-pulled carts, we utilize advanced CNC stamping and bending equipment to ensure the dimensional accuracy of every part. Simultaneously, we strictly follow the ISO 9001 quality management system, conducting repeated tests on the durability and safety of every folding mechanism, ensuring that the product achieves ultimate portability without sacrificing its core load-bearing function.

5. From Production to Quality Control: ISO 9001 Quality Management Practices for Heavy-Duty Steel Plate Hand Carts

A high-quality heavy-duty steel plate hand cart is the result of a systematic quality management process. This article demonstrates the full-process quality control practices for heavy-duty steel plate hand carts under the ISO 9001 quality management system framework, from raw material inspection and production process control to finished product testing. It highlights key quality control points such as weld strength testing, load testing, and surface finish inspection.

Key Quality Control Points and Standards

- Raw Material Inspection: Sampling inspection of steel plate thickness, hardness, and surface quality to ensure compliance with design requirements.

- Welding Quality: Visual inspection of welds and sampling destructive testing to ensure no weak or false welds.

- Load Testing: Finished products must pass a static load test of 1.5 times the rated load for 5 minutes to check for permanent deformation.

- Surface Treatment: Salt spray testing (typically ≥48 hours) and adhesion tests to ensure the anti-corrosion capability and durability of the powder coating.

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

Jiaxing Lanyue Metal Technology Co., Ltd. has established and implemented a comprehensive ISO 9001 quality management system, which is the cornerstone of our commitment to our customers. We firmly believe that excellent quality is achieved through manufacturing, not just inspection. Therefore, we integrate quality awareness into every production step, from employee training and equipment maintenance to process optimization and customer feedback, forming a closed loop of continuous improvement. We strive to become a leading supplier in the precision manufacturing of metals and plastics, moving forward hand in hand with our partners through stable, reliable, high-quality products.

FAQ

What is the difference between a hand truck and a flatbed cart?

The primary difference lies in their design and intended use. A hand truck, also known as a dolly, has a vertical frame with two large wheels and a small toe plate (ledge) to slide under items. It's designed for moving tall, stackable items like boxes or appliances, leveraging gravity to balance the load. A flatbed cart, on the other hand, has a horizontal platform (the flatbed) sitting on four (or more) wheels. It's designed for carrying wide, bulky, or numerous items that cannot be easily stacked, such as large boxes, equipment, or multiple smaller items. The choice depends on the shape and size of the items you need to move.

How do I choose the right wheel type for my hand cart?

Choosing the right wheel is crucial for performance and longevity. Consider these factors: 1) Floor Surface: For smooth indoor floors like tile or concrete, PU (polyurethane) wheels are ideal as they are quiet and non-marking. For rough outdoor surfaces like asphalt or gravel, pneumatic (air-filled) or solid rubber wheels provide better shock absorption. 2) Load Capacity: Heavier loads require more robust wheels. Iron core wheels are best for extreme weights. 3) Environment: If you're working in a wet or corrosive environment, look for wheels with corrosion-resistant materials like polypropylene or stainless steel. 4) Maneuverability: Swivel casters on all four corners offer maximum maneuverability, while a combination of fixed and swivel casters provides easier straight-line tracking.

What is the weight capacity of a typical heavy-duty hand cart?

The weight capacity of a heavy-duty hand cart varies widely based on its construction and design. Generally, a "heavy-duty" model starts around 300-500 kg (660-1100 lbs). However, specialized industrial-grade carts, often built with reinforced steel frames and heavy-duty iron core wheels, can have capacities ranging from 800 kg (1760 lbs) to over 1000 kg (2200 lbs). It's critical to check the manufacturer's specified load capacity and never exceed it. Always consider the weight of the cart itself when calculating total load, and factor in a safety margin for dynamic loads (the extra force exerted when the cart is moving over bumps.

Are folding hand carts as strong as non-folding ones?

Generally, non-folding (fixed-frame) hand carts are stronger than their folding counterparts. The folding mechanisms, such as joints and locks, can be potential points of stress and weakness compared to a solid, welded frame. However, this doesn't mean folding carts are weak. High-quality folding hand carts are engineered with reinforced joints and robust locking mechanisms to offer impressive strength, often with capacities of 150-300 kg. The trade-off is always between ultimate strength/durability and portability/convenience. If you need maximum capacity for very heavy, industrial tasks, a fixed-frame cart is better. For versatility, storage, and transport, a well-built folding cart is an excellent and often sufficiently strong choice.

How do I maintain my steel hand cart to ensure a long life?

Proper maintenance will significantly extend the life of your steel hand cart. Follow these key steps: 1) Regular Cleaning: Wipe down the steel frame and deck regularly, especially after use in wet or dirty environments, to prevent rust and corrosion. 2) Wheel and Axle Care: Periodically check the wheels for debris buildup (like string or hair) and clear it. Ensure the axles are tight and lubricate them with a suitable grease or oil if they start to squeak or turn roughly. 3) Inspect the Frame: Check for any signs of cracks, especially around the welds and folding joints. 4) Check Fasteners: Tighten any loose bolts or screws on the frame or wheels. 5) Address Rust Immediately: If you see any scratches or chips in the paint that have started to rust, clean the area and touch it up with rust-resistant paint to prevent it from spreading.

English

English  Español

Español  Deutsch

Deutsch

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

+86-137 0583 8919+86-135 8638 0656

+86-137 0583 8919+86-135 8638 0656