1. Beyond the Standard: The Custom Design Process and Key Parameter Considerations for Non-Standard Accessory Bearings

When standard bearings fail to meet the specific performance, spatial, or functional requirements of a piece of equipment, Non-Standard Accessory Bearings become the ideal solution. This article details the custom design process for non-standard bearings, from initial requirement analysis to final mass production, and highlights the critical parameters that must be considered during the design phase, such as special dimensions, irregular shapes, integrated functions, and material selection.

Key Parameter Considerations

- Dimensional Tolerances: Defining tight tolerances for inner/outer diameter and width (e.g., ±0.005mm) based on fitting requirements.

- Material Selection: Moving beyond standard bearing steel to choose stainless steel, ceramics, or engineering plastics for special environments like corrosion, high temperature, or electrical insulation.

- Sealing Solutions: Customizing seal lip shape, material, and contact pressure to handle specific contaminants (e.g., dust, liquid splash).

- Integrated Functions: Designing integrated structures such as flanges, gears, pull rods, or sensor mounts.

- Lubrication Requirements: Selecting special greases or solid lubrication solutions based on temperature, speed, and load.

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

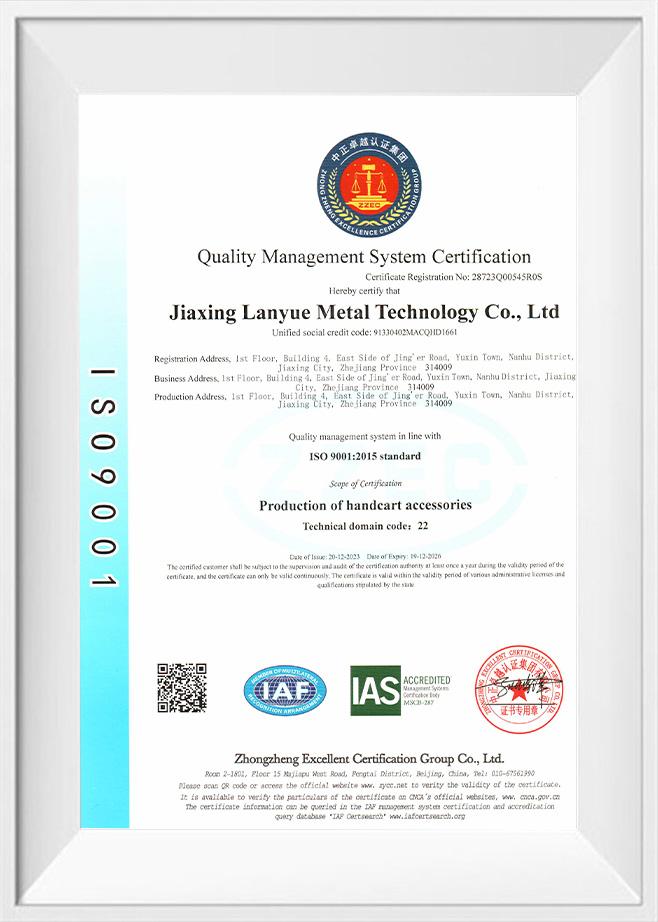

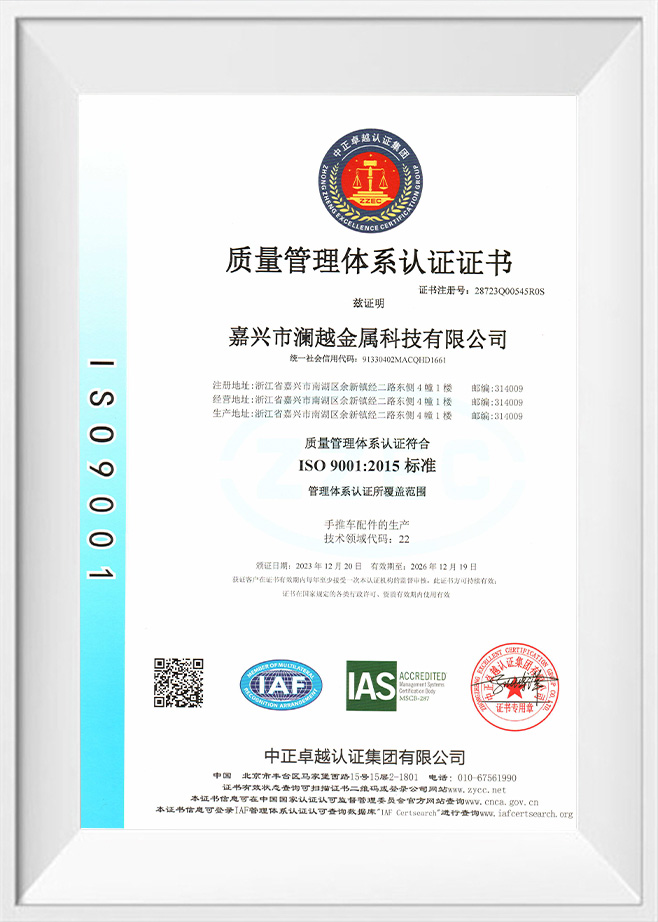

As a leading enterprise specializing in the research, development, and production of precision metal and engineering plastic products, one of Jiaxing Lanyue Metal Technology Co., Ltd.'s core strengths is providing highly customized component solutions. We strictly adhere to the ISO 9001 quality management system, working closely with clients from the initial stage of each project to ensure that the design parameters of every non-standard accessory bearing precisely meet its unique application scenario, transforming the customer's innovative concepts into reliable products.

2. From 608RS to Integrated Bearings: Load and Life Analysis of Non-Standard Accessory Bearings in Specific Applications

The performance evaluation of non-standard accessory bearings cannot simply apply standard models. This article uses the common 608RS skateboard bearing and a heavy-duty integrated bearing capable of handling 300kg as examples to deeply analyze their load characteristics in specific applications (such as high-frequency impact and heavy static loads) and explores how to significantly extend their service life through optimized design and material selection.

Comparative Analysis of Key Parameters

| Bearing Type |

Dynamic Load Rating (C) |

Static Load Rating (Co) |

Application Features |

Life-Influencing Factors |

| 608RS (for Skateboards) |

~1.28 kN |

~0.66 kN |

High speed, strong impact, vibration |

Impact loads, sealing waterproofness, grease stability |

| Integrated Bearing (300kg) |

~5.0 kN (custom) |

~12.0 kN (custom) |

Low speed, heavy load, compact structure |

Contact stress, material fatigue, installation alignment accuracy |

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

Jiaxing Lanyue Metal Technology Co., Ltd. consistently adheres to the philosophy of "Striving for Excellence, Innovating for the Future," using technological innovation to deeply understand and solve bearing life problems under complex working conditions. We not only provide products but also solutions based on working condition analysis. Through advanced simulation technology and material science, we optimize the load distribution for our clients' non-standard accessory bearings, extend their service life, and earn customer trust with superior quality.

3. Material Innovation: Application and Performance Comparison of Engineering Plastics and Specialty Metals in Non-Standard Accessory Bearings

Material selection for non-standard accessory bearings is no longer limited to traditional bearing steel. This article explores the application of engineering plastics (such as PEEK, POM) and specialty metals (like AISI 440C stainless steel, ceramics) in non-standard bearings. Through specific parameter comparisons, it analyzes their unique advantages in terms of corrosion resistance, lightweight design, electrical insulation, and dry-running capabilities.

Key Material Performance Parameters

- PEEK (Engineering Plastic):

- Density: ~1.3 g/cm³ (lightweight)

- Continuous Service Temperature: 250°C

- Features: Excellent chemical resistance, self-lubricating, electrically insulating

- 440C Stainless Steel:

- Hardness: HRC 58-60 (after heat treatment)

- Features: Excellent corrosion resistance, high hardness

- Ceramic (Si3N4):

- Density: ~3.2 g/cm³

- Features: Extremely high hardness, high-temperature resistance, electrically insulating, non-magnetic

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

Located in the core manufacturing region of the Yangtze River Delta, Jiaxing Lanyue Metal Technology Co., Ltd. has expertise spanning both precision metal and engineering plastics. This unique composite advantage allows us to provide clients with the most comprehensive material solutions. We are proficient in the processing techniques and performance boundaries of different materials, enabling us to recommend and manufacture the most suitable non-standard accessory bearings according to specific customer needs (e.g., in the food, medical, or chemical industries), achieving the optimal balance between performance and cost.

4. The Cornerstone of Precision Manufacturing: Tolerance Control and ISO 9001 Quality Management Practices for Non-Standard Accessory Bearings

For non-standard accessory bearings, precise tolerance control is the lifeline ensuring their functionality and interchangeability. This article interprets the key tolerance items for non-standard bearings (such as inner/outer diameter roundness, raceway wobble, perpendicularity) and demonstrates how, under an ISO 9001 quality management system, consistency and reliability are guaranteed through process control, precision inspection, and continuous improvement.

Example of Key Tolerance Parameters (P4 Accuracy Class)

- Inner Diameter Tolerance: 0 ~ -4 μm

- Outer Diameter Tolerance: 0 ~ -6 μm

- Inner Ring Radial Runout: ≤ 3 μm

- Outer Ring Radial Runout: ≤ 5 μm

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

Jiaxing Lanyue Metal Technology Co., Ltd. has established and implemented a comprehensive ISO 9001 quality management system. We deeply understand that for non-standard products, the definition of quality lies in "conforming to the customer's explicit specifications and potential needs." Therefore, we have invested in high-end inspection equipment such as coordinate measuring machines and roundness testers to strictly monitor every production step, ensuring that every non-standard accessory bearing delivered to the client is a testament to our precision manufacturing capabilities.

5. Application-Driven Innovation: How Non-Standard Accessory Bearings Empower the Diversified Development of Emerging Industries

From the silent operation of smart home appliances to the flexible steering of logistics robots and the precise transmission of medical devices, the rise of emerging industries has posed unprecedented challenges to components. This article, through multiple case studies, demonstrates how non-standard accessory bearings solve specific industry pain points through customized design, such as reducing noise, minimizing size, and integrating sensor functions, thereby becoming key components that drive technological innovation.

Key Application Cases and Parameters

- Smart Home Appliances (e.g., Washing Machines):

- Requirement: Ultra-quiet operation, moisture resistance

- Solution: Motor bearings with asymmetric seals and special low-noise grease.

- Service Robots:

- Requirement: Lightweight, high responsiveness

- Solution: Thin-walled, integrated joint bearings with flanges.

- Medical Devices (e.g., Infusion Pumps):

- Requirement: Biocompatibility, electrical insulation

- Solution: Non-standard bearings made entirely of PEEK or ceramic hybrid materials.

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

Jiaxing Lanyue Metal Technology Co., Ltd. strives to become a leading supplier in the precision manufacturing of metals and plastics. We are not just manufacturers of components; we are partners on our customers' innovation journey. We actively collaborate with leading companies in various industries to deeply understand the future development direction of their products, conduct early technical reserves and product R&D, and create shared value with our clients by providing diversified, high-quality non-standard accessory bearing solutions, jointly promoting industrial progress.

FAQ

What is the typical lead time for a custom non-standard accessory bearing?

The lead time for a custom non-standard bearing can vary significantly based on complexity, material availability, and order quantity. Generally, the process involves design confirmation, material procurement, prototype manufacturing, testing, and mass production. For a moderately complex design, the lead time can range from 4 to 8 weeks. The initial design and prototyping phase might take 2-3 weeks, followed by another 2-5 weeks for production after final approval. It's always best to discuss your project timeline with the manufacturer early in the process to ensure a realistic schedule.

How much does it cost to develop a non-standard bearing compared to a standard one?

Developing a non-standard bearing involves higher upfront costs compared to purchasing a standard, off-the-shelf bearing. These costs include R&D, design, creating custom tooling (dies, molds), and setting up a unique production process. The unit cost is also typically higher due to smaller production runs and more specialized materials or processes. However, this investment often pays off by enabling a unique product feature, improving overall system performance, reducing total assembly costs, or extending the life of the final product. The value is measured in system-level benefits rather than just the component price.

What information is needed to get a quote for a custom non-standard bearing?

To provide an accurate quote, a manufacturer needs detailed information. The most critical elements include: 1) Detailed Drawings or 3D Models: Showing all dimensions, tolerances, and surface finish requirements. 2) Material Specification: The exact grade of steel, plastic, or ceramic required. 3) Load and Speed Data: Estimated radial and axial loads, and the operating speed (RPM). 4) Application Environment: Information about temperature, exposure to chemicals or moisture, and cleanliness levels. 5) Quantity: The estimated annual usage and order quantity per batch. 6) Special Requirements: Such as specific lubricants, sealing needs, or testing requirements. The more detailed your information, the more accurate and faster the quotation will be.

Can non-standard accessory bearings be made from ceramic or plastic materials?

Absolutely. The choice of material for non-standard bearings is driven by the application's specific needs. Ceramic bearings (often hybrid with steel races) are chosen for their extreme hardness, high-temperature capability, corrosion resistance, and non-magnetic, electrically insulating properties, making them ideal for high-speed spindles, chemical processing, and semiconductor equipment. Plastic bearings (like those made from PEEK, PTFE, or POM) are lightweight, self-lubricating, resistant to corrosion, and can operate quietly without lubrication. They are perfect for food processing, medical devices, and applications where weight and noise are critical concerns. The non-standard design process allows for the optimal selection of these advanced materials.

What are the common challenges in designing non-standard bearings?

Designing non-standard bearings presents several unique challenges. 1) Balancing Conflicting Requirements: For instance, a need for high load capacity in a very compact space can create design trade-offs. 2) Material and Process Selection: Choosing the right material that can be manufactured to the required tolerances and perform under specific conditions is complex. 3) Lubrication and Sealing: Ensuring effective lubrication and sealing in an unconventional design requires careful engineering to prevent premature failure. 4) Cost Management: Keeping the design manufacturable and cost-effective while meeting all performance criteria is a constant challenge. 5) Testing and Validation: Developing a robust testing plan to validate the custom bearing's performance and life under real-world conditions is crucial but can be resource-intensive.

English

English  Español

Español  Deutsch

Deutsch

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

+86-137 0583 8919+86-135 8638 0656

+86-137 0583 8919+86-135 8638 0656