1. A Selection Guide for 6200 Series Deep Groove Ball Bearings: Key Parameters from 6200 to 6209

This article serves as a detailed selection guide for engineers and procurement professionals focusing on the Deep Groove Ball Bearings 6200-6209 series. We will analyze the core technical parameters for each model, from 6200 to 6209, including inner diameter, outer diameter, width, dynamic load rating, and static load rating. This information will assist you in making the optimal choice based on specific operating conditions such as speed, load, and installation space.

Key Parameter Example (Model 6204)

- Inner Diameter (d): 20 mm

- Outer Diameter (D): 47 mm

- Width (B): 14 mm

- Dynamic Load Rating (C): 9.8 kN

- Static Load Rating (Co): 5.0 kN

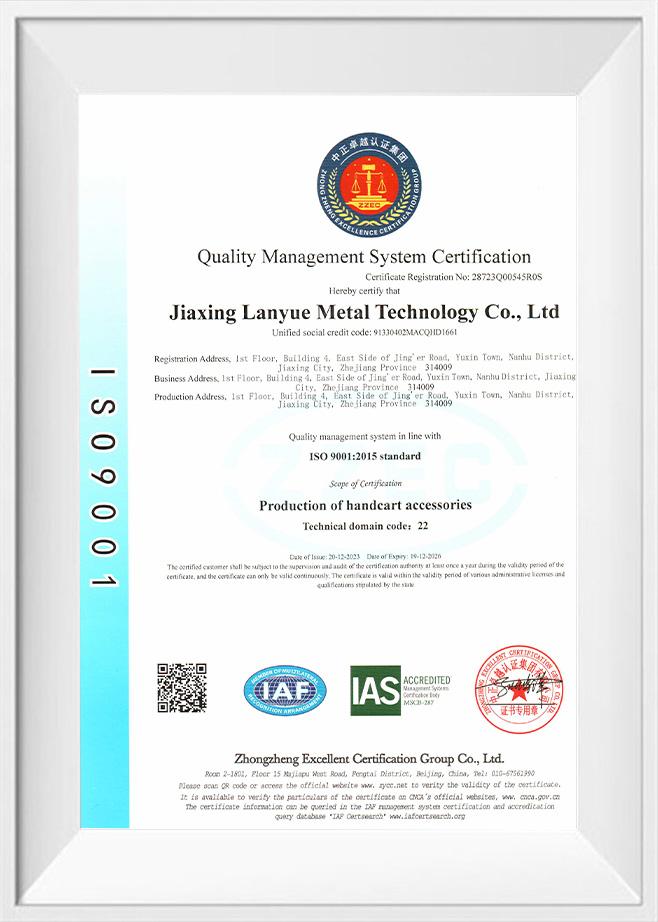

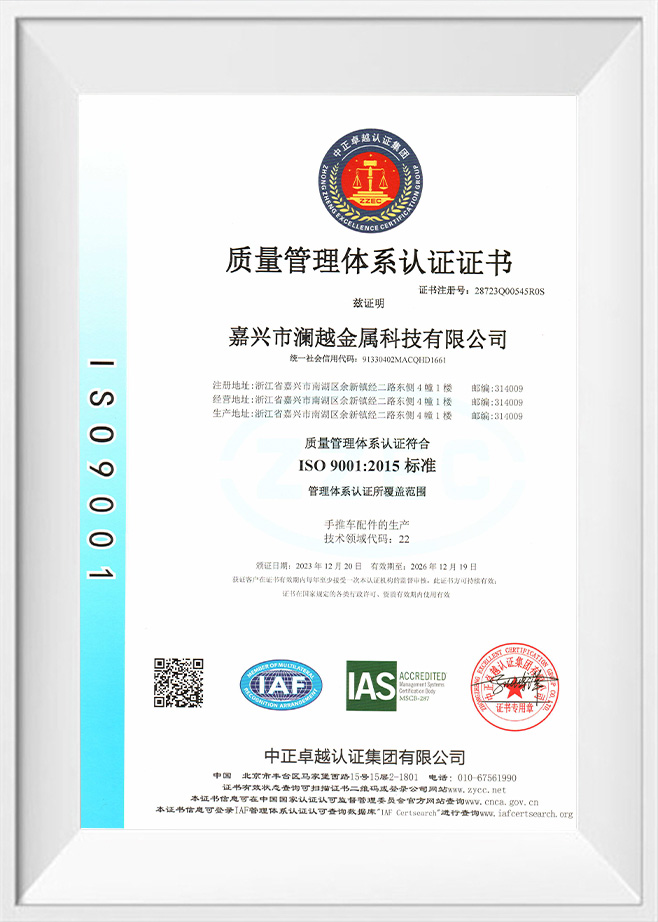

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

As a leading enterprise specializing in the research, development, and production of precision metal products, Jiaxing Lanyue Metal Technology Co., Ltd. deeply understands the importance of precise parameter matching for equipment performance. We strictly adhere to the ISO 9001 quality management system, ensuring that the dimensional accuracy and performance parameters of every 6200 series bearing meet international standards, providing reliable and efficient transmission solutions for industrial customers worldwide.

2. In-depth Analysis: Load Ratings and Life Calculation for 6200 Series Bearings – A Case Study on 6206 and 6208

The load capacity of a bearing directly determines its service life and equipment reliability. This article explores the concepts of dynamic and static load ratings for deep groove ball bearings and demonstrates how to calculate the basic rated life of a bearing based on actual operating conditions, using the common models 6206 and 6208 as examples.

Key Parameter Comparison

| Model |

Dynamic Load Rating (C) |

Static Load Rating (Co) |

Limiting Speed (Grease) |

| 6206 |

15.0 kN |

7.8 kN |

19,000 rpm |

| 6208 |

22.5 kN |

11.8 kN |

16,000 rpm |

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

Jiaxing Lanyue Metal Technology Co., Ltd. consistently adheres to the philosophy of "Striving for Excellence, Innovating for the Future," continuously enhancing product performance through technological innovation. Our 6200 series bearings not only possess excellent load parameters but also excel in material heat treatment and manufacturing processes, ensuring that the products meet or exceed theoretically calculated lifespans in practical applications, thereby earning the long-term trust of our customers.

3. Beyond the Basics: Analyzing the Limiting Speed and Application Boundaries of 6200 Series Deep Groove Ball Bearings

Limiting speed is a critical indicator in bearing selection, directly affecting the high-speed operation capability of equipment. This article analyzes the factors that influence the limiting speed of the 6200 series (such as lubrication method, load, and accuracy class) and explores its application boundaries in high-speed motors, power tools, and other fields.

Key Parameter Examples (Limiting Speed)

- 6201: 28,000 rpm

- 6203: 24,000 rpm

- 6205: 20,000 rpm

- 6209: 15,000 rpm

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

Located in the core manufacturing region of the Yangtze River Delta, Jiaxing Lanyue Metal Technology Co., Ltd. is dedicated to providing diversified, high-quality component solutions to global industrial customers. We are well aware of the stringent speed requirements of different industries. Therefore, our 6200 series bearings are designed and manufactured with full consideration for stability and durability during high-speed operation, making them an ideal choice for your high-speed applications.

4. Industrial Application Case Studies: How the 6200 Series Bearings Empower Diverse Industries from Home Appliances to Automotive

The 6200 series deep groove ball bearings are widely used due to their simple structure and reliable performance. This article showcases their critical roles in various sectors through specific cases, such as in home appliances (e.g., washing machines, fans) and automotive components (e.g., alternators, water pumps), using models like 6202 and 6207.

Key Parameters and Application Correlation

- 6202 (15mm bore): Commonly used in small motors and drive shafts, its compact size and 5.9 kN dynamic load rating are sufficient to handle most light-load scenarios.

- 6207 (35mm bore): Suitable for medium-power automotive alternators and industrial water pumps, its 19.5 kN dynamic load rating ensures reliability under complex operating conditions.

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

Jiaxing Lanyue Metal Technology Co., Ltd. strives to become a leading supplier in the precision manufacturing of metals and plastics. We provide customized bearing solutions for different industries. Through superior quality and comprehensive services, we work hand in hand with our partners to create shared value and jointly promote technological advancement across various sectors.

5. From Material to Manufacturing: Quality Control and Production Practices for 6200 Series Bearings under the ISO 9001 System

The quality of a bearing stems from strict control over every stage of production. This article details the entire process for the 6200 series, from raw material selection (e.g., high-carbon chromium bearing steel) and heat treatment to precision grinding and assembly. It also explains how the ISO 9001 quality management system is implemented throughout the entire workflow.

Key Parameters and Quality Control

- Material Hardness: HRC 61-65 (ensuring high wear resistance and contact fatigue strength)

- Rotational Accuracy: P0/P6/P5 tolerance classes (meeting the precision requirements of different applications)

- Vibration Level: Z1/Z2/Z3/V1/V2/V3 grades (controlling operational noise and enhancing user experience)

Integration with Jiaxing Lanyue Metal Technology Co., Ltd.

Jiaxing Lanyue Metal Technology Co., Ltd. has established and implemented a comprehensive ISO 9001 quality management system. From raw material inspection to final product delivery, every step follows rigorous testing standards. We firmly believe that only through systematic quality management and an unwavering pursuit of excellence can we provide trustworthy precision metal products to global customers and fulfill our commitment to "Striving for Excellence, Innovating for the Future."

FAQ

What is the difference between 6200, 6201, and 6202 bearings?

The primary difference between these models lies in their dimensions, specifically the inner and outer diameters. The 6200 bearing has a 10mm inner diameter and 30mm outer diameter. The 6201 has a 12mm inner diameter and 32mm outer diameter. The 6202 features a 15mm inner diameter and 35mm outer diameter. As the model number increases, so do the dimensions and, consequently, the load-carrying capacity. Selecting the correct model depends on the shaft diameter and the space constraints of your application.

How do I choose the right lubrication for a 6200 series bearing?

Choosing the right lubrication is crucial for bearing performance and longevity. The choice depends on operating speed, temperature, and load. For general applications under 15,000 rpm, high-quality lithium-based grease is a common choice. For higher speeds or specific temperature ranges, a specialized synthetic grease or even oil lubrication might be necessary. Oil lubrication offers better heat dissipation and is suitable for very high-speed applications, while grease is simpler to contain and requires less maintenance. Always refer to the manufacturer's recommendations for the specific operating conditions.

Can a 6205 ZZ bearing handle axial loads?

Yes, a 6205 ZZ bearing (which indicates metal shields on both sides) can handle axial loads, but its capacity is limited. Deep groove ball bearings are primarily designed to support radial loads. However, due to their raceway geometry, they can also accommodate moderate axial loads in both directions. The axial load capacity is typically a fraction of its radial load capacity. For applications with significant or continuous axial forces, an angular contact ball bearing would be a more suitable choice.

What do the suffixes like 2RS, ZZ, or C3 mean for 6200 series bearings?

These suffixes indicate specific variations in the bearing's design or tolerance. ZZ (or 2Z) means the bearing has metal shields on both sides to protect against solid contaminants. 2RS indicates it has rubber seals on both sides, offering better protection against moisture and fine particles, though with slightly higher friction. C3 denotes an internal clearance greater than normal; this is used for applications that may experience high temperatures or high speeds, where thermal expansion could reduce the internal clearance. Selecting the right suffix ensures the bearing performs optimally in its intended environment.

How do I properly install a 6203 deep groove ball bearing to avoid damage?

Proper installation is key to preventing premature bearing failure. First, ensure the shaft and housing are clean and have the correct dimensions. Apply pressure only to the ring that is being mounted (e.g., press the inner ring onto the shaft). Use a mechanical press or a bearing installation tool. Never apply pressure through the rolling elements (balls) or the seals, as this will cause damage. Align the bearing carefully to avoid cocking. Forcing a misaligned bearing can create brinelling (dents) on the raceways. Using heat to expand the inner ring for a tight-fit application is a recommended practice for safe and correct installation.

English

English  Español

Español  Deutsch

Deutsch

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

+86-137 0583 8919+86-135 8638 0656

+86-137 0583 8919+86-135 8638 0656