In modern mechanical systems, deep groove ball bearings are almost ubiquitous – from motors and transmission equipment to household appliances and automated equipment, their small size belies their crucial role in high-speed, low-friction, and long-life operation. But why have deep groove ball bearings become the most widely used and in-demand type of bearing in the engineering field? What are their irreplaceable advantages?

Where do the structural advantages of deep groove ball bearings come from?

The structure of deep groove ball bearings seems simple, yet it embodies engineering ingenuity. The inner ring, outer ring, steel balls, and retainer constitute its core, and the “deep groove” design allows the steel balls to rotate stably in the groove, providing excellent load-bearing and stability performance.

-

High speed and low friction: the key to efficiency

Deep groove ball bearings can maintain stable operation at high speeds while having a low coefficient of friction. Therefore, they are very suitable for high-speed rotating motors, machine spindles, and other applications.

-

Accommodating both radial and certain axial loads

Although they primarily bear radial loads, the deep groove structure also allows them to withstand bidirectional axial loads, making their applications even more widespread.

-

Easy installation and simple maintenance

Compared to bearings with complex structures, deep groove ball bearings do not require high installation precision, and their maintenance cycle is relatively long, making them one of the most “trouble-free” core components in many pieces of equipment.

Why are deep groove ball bearings the first choice for many industries?

The range of applications for deep groove ball bearings is surprisingly wide, covering almost all processing and manufacturing-related fields. Taking standard models such as the 6202, 6200, 6201, 6203, 6204, 6205, 6206, 6207, 6208, and 6209 series deep groove ball bearings as examples, each size is widely used in different nodes of mechanical systems.

Industrial equipment: ensuring stable operation

In assembly line equipment, transmission machinery, and motor systems, deep groove ball bearings undertake the task of continuous high-intensity operation. Their high speed and durability perfectly match the needs of industrial automation. Home Appliances: The Combination of Silence and Reliability

In products such as washing machines, electric fans, and vacuum cleaners, noise control and long-term durability are crucial. Deep groove ball bearings are a key factor in achieving quiet and long-lasting operation.

Automotive Sector: Ensuring Smooth and Safe Driving

From motors and compressors to transmission systems, deep groove ball bearings leverage their low friction and high load capacity advantages in automotive components, bringing greater reliability to vehicle operation.

Jiaxing Lanyue Metal Technology Co., Ltd.: Where Does the Strength in Deep Groove Ball Bearing Manufacturing Come From?

As a factory, manufacturer, and wholesale supplier of 6202~6209 series deep groove ball bearings in China, Jiaxing Lanyue Metal Technology Co., Ltd. is based in Jiaxing, Zhejiang – a core manufacturing region in the Yangtze River Delta – providing high-level bearing products to global customers with its professional R&D and manufacturing capabilities.

-

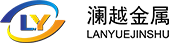

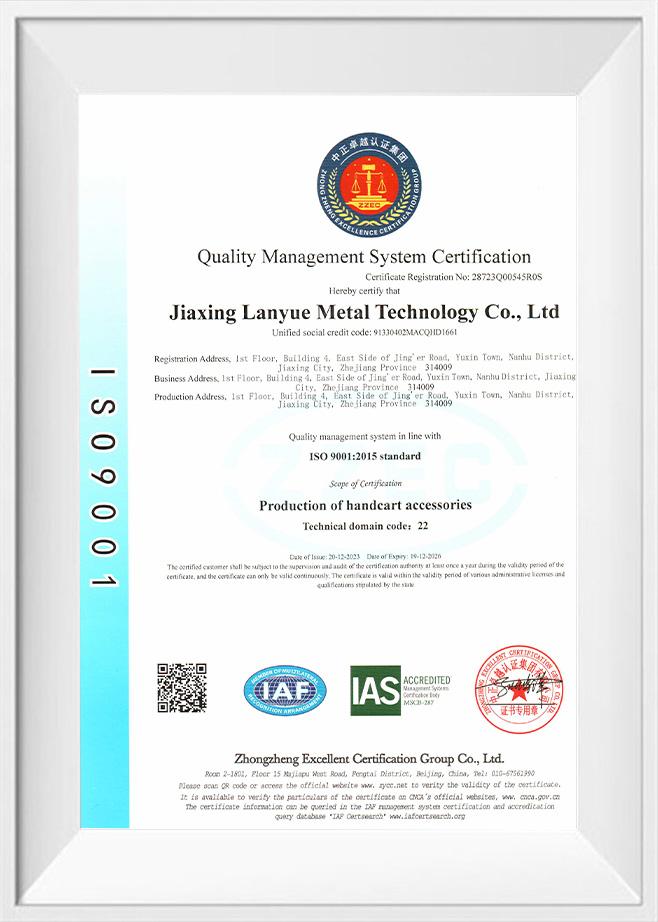

ISO 9001 Comprehensive Quality System Guarantee

We strictly implement the ISO 9001 quality management system in our production process, from raw material inspection and processing precision control to finished product testing, ensuring the stable performance and service life of every bearing from multiple dimensions.

-

Strong Precision Metal Processing Capabilities, Adaptable to Various Application Scenarios

Jiaxing Lanyue Metal Technology Co., Ltd. focuses on precision manufacturing of metals and engineering plastics. Our technical team continuously innovates, enabling our deep groove ball bearings to reach advanced industry levels in terms of dimensional error control, surface finish, and structural stability.

-

Strong Supply Capacity and Complete Range of Models

Whether it’s the standard 6202, 6200, 6201, 6203, 6204, 6205, 6206, 6207, 6208, 6209 models, or customized sizes, we can deliver quickly to meet the diverse needs of global customers.

-

R&D Drives the Future, Continuous Innovation

The company adheres to the philosophy of “pursuing excellence and innovating for the future,” driving product upgrades through technological innovation, continuously improving manufacturing capabilities, and creating value together with global partners.

From Materials to Manufacturing: Why is Deep Groove Ball Bearing Quality So Crucial?

The lifespan and performance of deep groove ball bearings depend on multiple factors, including materials, heat treatment, processing precision, and lubrication system. High-quality bearings must meet the following conditions:

High-Purity Bearing Steel

The higher the purity of the bearing steel, the longer the fatigue life and the better the wear resistance. Lanyue Metal Technology strictly selects high-standard materials to ensure a dense and uniform internal structure.

Precision Machining Equipment Guarantees Dimensional Accuracy

High-precision turning and grinding equipment ensure that all dimensions meet strict tolerance requirements, guaranteeing that the bearings do not produce excessive vibration during high-speed rotation.

Multi-Stage Heat Treatment Enhances Durability

Appropriate heat treatment gives the bearings high hardness and excellent toughness, increasing their lifespan and reducing the risk of wear.

Why is the deep groove ball bearing market still booming?

With the development of new energy vehicles, intelligent manufacturing, robotics, and light industrial equipment, the demand for deep groove ball bearings continues to rise. Their reliable, economical, and easy-to-maintain characteristics make them an important basic component for many types of equipment. In the context of a volatile global supply chain, manufacturers with stable supply and reliable quality are even more important.

Jiaxing Lanyue Metal Technology Co., Ltd., relying on the advanced manufacturing chain in the Yangtze River Delta, a continuously innovative R&D system, and rigorous quality control, provides stable and high-quality deep groove ball bearings to customers at home and abroad, and is a preferred long-term partner for many enterprises.

FAQ: What you might want to know about deep groove ball bearings—

Q1: What is the difference between deep groove ball bearings and angular contact ball bearings?

A: Deep groove ball bearings can withstand radial and a small amount of axial load and have a simple structure; angular contact ball bearings are more suitable for unidirectional axial loads and are suitable for high-speed, high-rigidity applications.

Q2: How to determine if a bearing needs to be replaced?

A: Replacement should be considered if there is increased noise, overheating during operation, increased vibration, or lubrication failure.

Q3: Are deep groove ball bearings suitable for high-temperature environments?

A: Under reasonable material and lubrication conditions, they can adapt to certain high-temperature environments. Lanyue can provide high-temperature resistant solutions.

Q4: Does Jiaxing Lanyue Metal Technology Co., Ltd. support OEM/ODM?

A: Yes. We can provide customized deep groove ball bearing products according to customer drawings and application requirements. If you are looking for a reliable, durable, and comprehensive supplier of deep groove ball bearings, Jiaxing Lanyue Metal Technology Co., Ltd. will provide high-quality support for your projects with its professional manufacturing capabilities and strict quality assurance. We welcome you to contact us to discuss your technical and collaboration needs.

English

English  Español

Español  Deutsch

Deutsch

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

+86-137 0583 8919+86-135 8638 0656

+86-137 0583 8919+86-135 8638 0656