-

Lanyue Metal Technology

Lanyue Metal Technology

-

[email protected]/[email protected]

[email protected]/[email protected]

-

24 Hour Service - 7 Days a Week

24 Hour Service - 7 Days a Week

About Us

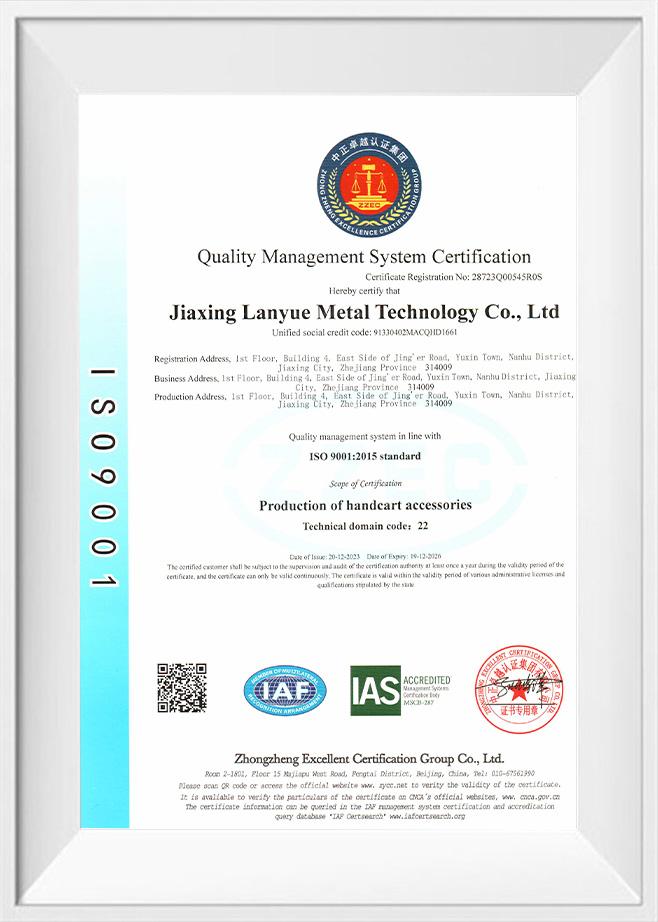

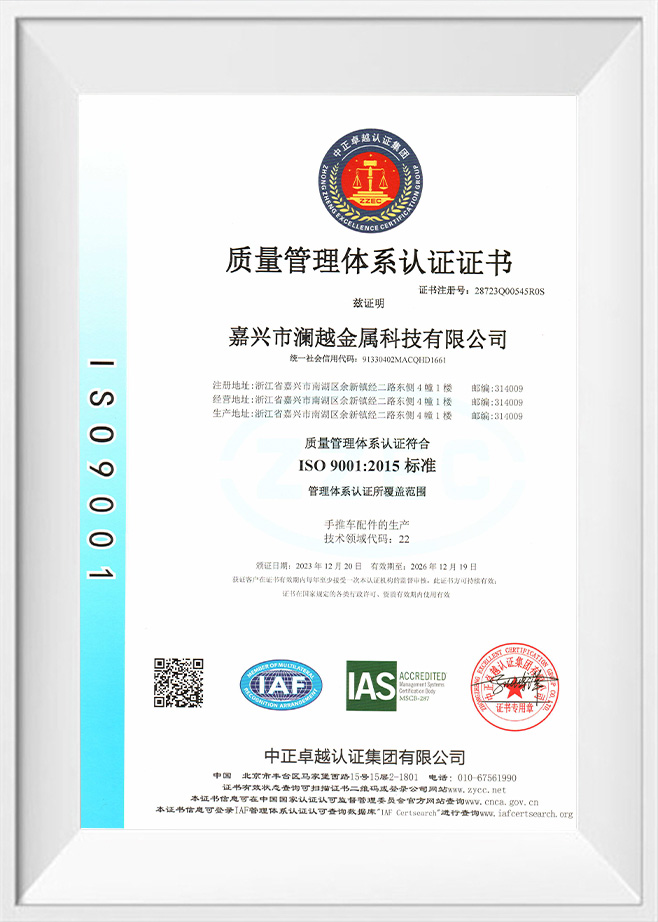

Jiaxing Lanyue Metal Technology Co., Ltd. is China Metal Rolling Bearing Suppliers and Custom Metal Rolling Bearing Manufacturers. It is a leading enterprise based in Jiaxing, Zhejiang, a core manufacturing region in the Yangtze River Delta. We specialize in the research, development, production, and sales of precision metal and engineering plastic products. Driven by innovation, we have established and implemented a comprehensive ISO 9001 quality management system, committed to providing diversified, high-quality component solutions to industrial customers worldwide.

Lanyue Metal Technology consistently adheres to the philosophy of "Striving for Excellence, Innovating for the Future," elevating manufacturing capabilities through technological innovation and earning customer trust with superior quality. We strive to become a leading supplier in the precision manufacturing of metals and plastics, working hand in hand with our partners to create shared value.

Honor

-

Quality Management System Certification

Quality Management System Certification -

Certificate of Quality Management System Certification

Certificate of Quality Management System Certification

News

-

Industry News 2026-02-24

In the realm of mechanical engineering, the metal rolling bearing serves as a fundamental component for reducing rotational friction and supporting axial or rad...

View More -

Industry News 2026-02-17

In the realm of structural engineering and heavy machinery, the integrity of a joint is only as reliable as its hardware. Carbon Steel Fasteners remain the back...

View More -

Industry News 2026-02-10

The modern automobile is a marvel of engineering, a complex symphony of thousands of parts working in unison. The integrity of this symphony depends not just on...

View More -

Industry News 2026-02-04

In the demanding world of modern manufacturing and heavy industry, the integrity of every assembly hinges on its smallest components. High-performance industria...

View More -

Industry News 2026-01-27

In the intricate world of industrial fastening, where the integrity of connections can determine the success or failure of a project, one component stands out f...

View More

Contact us now

What Are Metal Rolling Bearings and Why They Matter in Modern Machinery?

Metal rolling bearings are essential components widely used in industrial machinery, automotive systems, automation equipment, and precision devices. Their primary function is to reduce friction between moving parts, ensure stable rotation, and extend overall equipment life.

As a long-standing precision manufacturer, Jiaxing Lanyue Metal Technology Co., Ltd. is based in Jiaxing, Zhejiang — a core manufacturing region in the Yangtze River Delta. We specialize in R&D, production, and sales of precision metal and engineering plastic products. Driven by innovation and an implemented ISO 9001 quality management system, we are committed to providing diversified, high-quality component solutions to industrial customers worldwide.

Key Advantages of High-Quality Metal Rolling Bearings

1. Wear Resistance & Durability

Metal bearings are designed to withstand high-speed rotation, heavy loads, and harsh working environments including elevated temperatures, dust, and vibration.

2. High Precision & Stability

With advanced manufacturing processes, each bearing maintains stable rotation and minimal friction loss, helping users improve equipment efficiency and lifespan.

3. Material Diversity for Multiple Applications

Different industries require bearings with different material characteristics. Lanyue Metal offers customized metal and engineering plastic components to match diverse operational demands.

Comparison Table: Bearing Types & Typical Applications

| Bearing Type | Main Features | Typical Applications |

|---|---|---|

| Deep Groove Ball Bearing | Low friction, supports high rotation speed | Electric motors, pumps, household equipment |

| Tapered Roller Bearing | Supports combined radial and axial loads | Automotive industry, heavy machinery |

| Cylindrical Roller Bearing | High radial load capacity | Gearboxes, industrial transmission systems |

| Thrust Ball Bearing | Designed to withstand axial loads | Precision instruments, vertical machines |

| Needle Roller Bearing | Compact design with high load capacity | Automotive components, small devices |

Why Choose Lanyue Metal for Rolling Bearings?

Precision Manufacturing in the Yangtze River Delta

Located in Jiaxing, Zhejiang — one of China’s premium manufacturing hubs — we leverage a strong supply chain and advanced production facilities.

Strong R&D Capability

We continuously invest in innovation, following the philosophy "Striving for Excellence, Innovating for the Future." This ensures reliable and competitive products for global customers.

Comprehensive Quality Assurance

Our ISO 9001 quality management system guarantees consistent quality from raw material selection to final inspection.

Customized Bearing Solutions

We provide design, development, and production for high-precision metal and engineering plastic components to fully meet customer requirements.

How to Select the Right Metal Rolling Bearing

| Selection Factor | Customer Consideration |

|---|---|

| Load Type | Radial, axial, or combined load |

| Speed Requirement | Normal speed or high-speed rotation |

| Working Environment | Temperature, humidity, contamination level |

| Material & Coating | Chrome steel, stainless steel, carbon steel, special alloys |

| Precision Grade | Standard or high-precision for sensitive equipment |

| Mounting Structure | Shaft diameter, housing fit, available assembly space |

Maintenance Tips to Extend Bearing Life

- Use proper lubrication and select the correct grease or oil for the application.

- Protect bearings from contamination such as dust, metal chips, and moisture.

- Prevent overload and avoid misalignment during installation.

- Monitor temperature and noise levels regularly for early detection of issues.

- Replace worn bearings before they affect overall equipment safety.

FAQ — Common Customer Questions About Metal Rolling Bearings

Q1: How long can metal rolling bearings typically last?

Bearing life varies depending on operating speed, load, lubrication, and environment. Under proper conditions and maintenance, bearings can run for thousands to tens of thousands of hours.

Q2: Can Lanyue Metal customize special bearing sizes?

Yes. We specialize in custom precision metal and engineering plastic components and can provide tailored dimensions, materials, and performance grades to meet specific needs.

Q3: What materials are commonly used for metal bearings?

Common materials include chrome steel, stainless steel, carbon steel, and specialized alloys selected according to application requirements.

Q4: Do you provide OEM/ODM services?

Yes. We support OEM and ODM production with professional engineering support and strict confidentiality.

Q5: What industries commonly use your rolling bearings?

Our bearings are used across automotive, industrial machinery, automation, electronics, household appliances, and more.

Call to Action

If you need customized bearing solutions, technical drawings reviewed, or material recommendations, contact Jiaxing Lanyue Metal Technology Co., Ltd. Our engineering team can help evaluate your application and recommend the optimal bearing type and design.

English

English  Español

Español  Deutsch

Deutsch

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

+86-137 0583 8919+86-135 8638 0656

+86-137 0583 8919+86-135 8638 0656