-

Lanyue Metal Technology

Lanyue Metal Technology

-

[email protected]/[email protected]

[email protected]/[email protected]

-

24 Hour Service - 7 Days a Week

24 Hour Service - 7 Days a Week

About Us

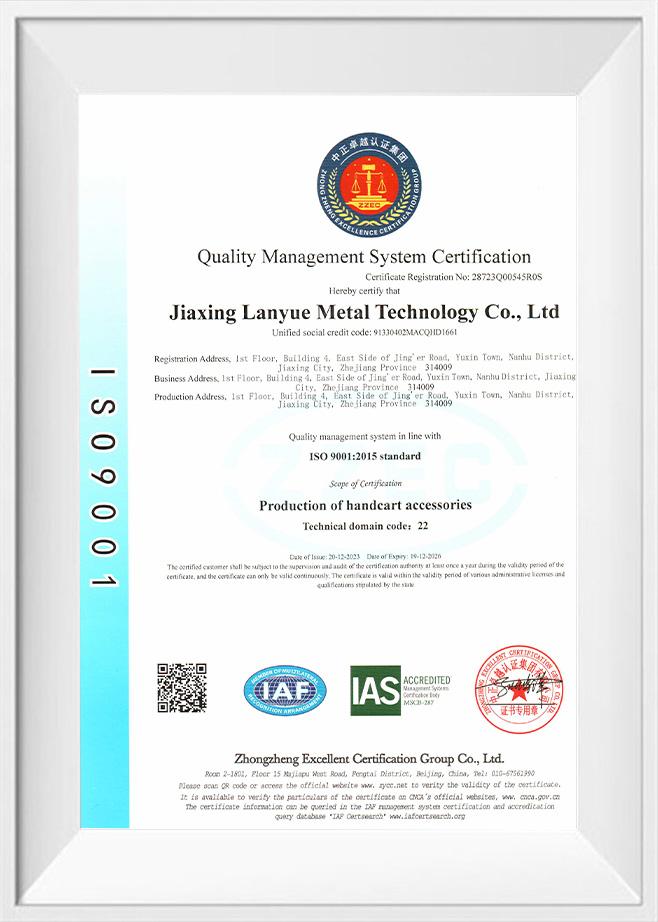

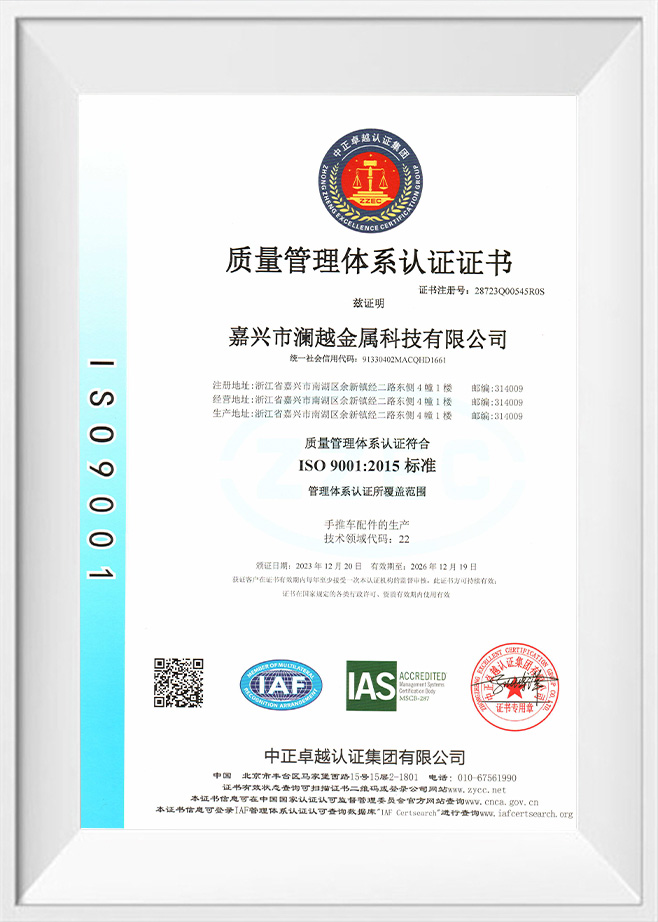

Jiaxing Lanyue Metal Technology Co., Ltd. is China Stainless Steel Fastener Hardware Suppliers and Custom Stainless Steel Fastener Hardware Manufacturers. It is a leading enterprise based in Jiaxing, Zhejiang, a core manufacturing region in the Yangtze River Delta. We specialize in the research, development, production, and sales of precision metal and engineering plastic products. Driven by innovation, we have established and implemented a comprehensive ISO 9001 quality management system, committed to providing diversified, high-quality component solutions to industrial customers worldwide.

Lanyue Metal Technology consistently adheres to the philosophy of "Striving for Excellence, Innovating for the Future," elevating manufacturing capabilities through technological innovation and earning customer trust with superior quality. We strive to become a leading supplier in the precision manufacturing of metals and plastics, working hand in hand with our partners to create shared value.

Honor

-

Quality Management System Certification

Quality Management System Certification -

Certificate of Quality Management System Certification

Certificate of Quality Management System Certification

News

-

Industry News 2026-02-24

In the realm of mechanical engineering, the metal rolling bearing serves as a fundamental component for reducing rotational friction and supporting axial or rad...

View More -

Industry News 2026-02-17

In the realm of structural engineering and heavy machinery, the integrity of a joint is only as reliable as its hardware. Carbon Steel Fasteners remain the back...

View More -

Industry News 2026-02-10

The modern automobile is a marvel of engineering, a complex symphony of thousands of parts working in unison. The integrity of this symphony depends not just on...

View More -

Industry News 2026-02-04

In the demanding world of modern manufacturing and heavy industry, the integrity of every assembly hinges on its smallest components. High-performance industria...

View More -

Industry News 2026-01-27

In the intricate world of industrial fastening, where the integrity of connections can determine the success or failure of a project, one component stands out f...

View More

Contact us now

What Makes Stainless Steel Fastener Hardware Essential in Modern Manufacturing

Stainless steel fastener hardware plays a critical role in ensuring structural integrity, corrosion resistance, and long term reliability across a wide range of industries. As manufacturing moves toward high precision and high durability standards, global demand for high performance stainless steel fasteners continues to grow.

For industrial users, selecting reliable fastener solutions helps reduce maintenance cost, improve equipment performance, and extend service life, especially under harsh or high load conditions.

Why Stainless Steel Fasteners Are Widely Preferred

- Excellent corrosion resistance for outdoor, chemical, and marine environments

- High tensile strength and strong durability

- Good temperature resistance and long term stability

- Clean and aesthetic appearance suitable for exposed installations

- Compatibility with materials such as aluminum, steel, composites, and plastics

These features make stainless steel fastener hardware essential for modern machinery, structural engineering, and precision manufacturing.

Common Stainless Steel Fastener Grades and Their Applications

| Stainless Steel Grade | Features | Typical Applications |

|---|---|---|

| 304 Stainless Steel | General corrosion resistance and balanced performance | Machinery, automotive, furniture, general industrial assembly |

| 316 Stainless Steel | Superior corrosion resistance for harsh environments | Marine equipment, chemical plants, outdoor facilities |

| 410 Stainless Steel | High hardness and excellent wear resistance | Tools, automotive parts, high strength applications |

| 2205 Duplex Stainless Steel | High strength combined with strong corrosion resistance | Offshore engineering, pressure vessels, precision structures |

Types of Stainless Steel Fastener Hardware

- Bolts including hex bolts, carriage bolts, and flange bolts

- Nuts including hex nuts, cap nuts, and lock nuts

- Screws including self tapping screws and machine screws

- Washers including flat washers, spring washers, and sealing washers

- Customized CNC precision components

- OEM and ODM metal and engineering plastic assembly parts

Industry Applications

Stainless steel fasteners produced by Jiaxing Lanyue Metal Technology Co Ltd are widely used in:

- New energy equipment

- Automotive and heavy machinery

- Marine engineering

- Construction and infrastructure

- Home appliances

- Textile machinery

- Electronics and smart devices

- Chemical and environmental equipment

How to Choose the Right Fastener

Match the Material to the Environment

- Indoor general use: 304

- Outdoor humidity and pollution: 316

- High strength requirement: 410 or 2205

Confirm Required Strength Grade

Consider tensile strength, torque requirements, and load conditions.

Consider Assembly Structure

Select the right thread type, length, head structure, and surface condition.

Verify Manufacturer Capability

A reliable manufacturer should have ISO 9001 certification, precision equipment, complete inspection systems, and stable delivery capability.

FAQ About Stainless Steel Fastener Hardware

Q1 How do I choose between 304 and 316 stainless steel

316 offers better corrosion resistance for coastal, outdoor, and chemical environments. For indoor or general industrial use, 304 is commonly sufficient.

Q2 Can stainless steel fasteners be magnetized

Austenitic stainless steel such as 304 or 316 is generally non magnetic, but slight magnetism may appear after cold working.

Q3 Do you support OEM or ODM customization

Yes. Lanyue Metal Technology provides custom fasteners and precision components based on drawings, samples, or specific application requirements.

Q4 How do you ensure consistent product quality

Quality is ensured through ISO 9001 control, strict inspection procedures, and complete material traceability.

Q5 What is the typical delivery time

Standard fasteners can be shipped quickly. Custom items usually require 7 to 25 days depending on complexity.

English

English  Español

Español  Deutsch

Deutsch

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

1st Floor, Building 4, East Side, Jinger Road, Yuxin Town, Nanhu District, Jiaxing City, Zhejiang Province, China

+86-137 0583 8919+86-135 8638 0656

+86-137 0583 8919+86-135 8638 0656